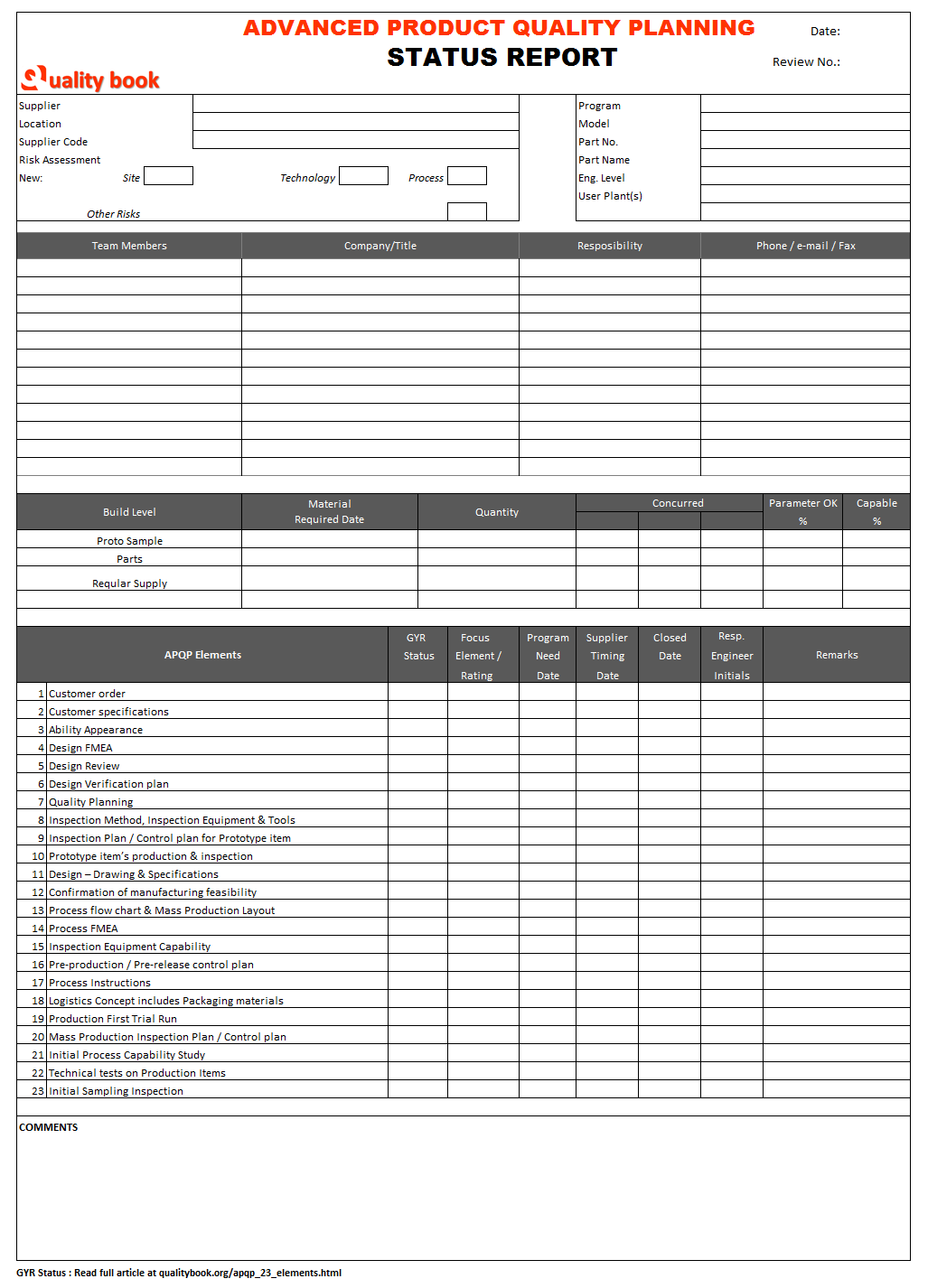

APQP 23 Elements

What is APQP 23 Elements?

List of APQP 23 Elements:

- Customer order

- Customer specifications

- Ability Appearance

- Design FMEA

- Design Review

- Design Verification plan

- Quality Planning

- Inspection Method, Inspection Equipment & Tools

- Inspection Plan / Control plan for Prototype item

- Prototype item's production & inspection

- Design - Drawing & Specifications

- Confirmation of manufacturing feasibility

- Process flow chart & Mass Production Layout

- Process FMEA

- Inspection Equipment Capability

- Pre-production / Pre-release control plan

- Process Instructions

- Logistics Concept includes Packaging materials

- Production First Trial Run

- Mass Production Inspection Plan / Control plan

- Initial Process Capability Study

- Technical tests on Production Items

- Initial Sampling Inspection

The purposes, expectations and requirements associated with documenting the individual elements of advanced product quality planning (APQP) status report. Here on qualitybook.org, I tried to describe each APQP element in easy language as well easier for understand and implement at real workplace. Let's see each element in deep:

Customer order

Customer specifications

Ability Appearance

Design FMEA

Design Review

Design Verification plan

Quality Planning

Inspection Method, Inspection Equipment & Tools

Inspection Plan / Control plan for Prototype item

Prototype item's production & inspection

Design - Drawing & Specifications

Confirmation of manufacturing feasibility

Process flow chart & Mass Production Layout

Process FMEA

Inspection Equipment Capability

Pre-production / Pre-release control plan

Process Instructions

Logistics Concept includes Packaging materials

Production First Trial Run

Mass Production Inspection Plan / Control plan

Initial Process Capability Study

Technical tests on Production Items

Initial Sampling Inspection

When any order received by supplier from customers, all the planning, schedules and investments are directly effects. The customers are explaining those expectations and decisions of suppliers for particular order for further documentation like nomination letters, APQP supporting documentation, and risk levels for particular order or product / process.

In along with customer's order, customer expecting some specific requirements to related its end applications, where expected design and drawing, technical sheets and other specific requirements enclosed for supplier understanding. The technical sheet and drawings are most important for engineering segment hence specifically needs to highlight and frequent communication required to comply all the requirements accordingly.

The supplier must be aware requirements of customers, and should be important to defined characteristics related auditability, handling and appearance mentioned, and the characteristics must be verified, and characteristics set and reference samples should be accessible with the customer.

To prevent defects during product design & development phase, a design FMEA needs to apply in the system to ensure potential design and development defects and their root causes identification, measurements and preventive actions. The cross functional team, conduct the design FMEA where all the functions of the product and must take into account practices and concern. The expectations from the design FMEA, is to all the problems related to product / process layout can identify and resolved during initial stages so that mass production schedule can be observed.

The targets of the design review are to prevent confusions and problems, observing the progress of processes and, to ensure that the purposes meet the requirements and all the verification should be conducted according to design verification plan. Reviews on potential improvements as concern product reliability and manufacturing cost, quality costs and planning.

It is supplier responsibility to effectively implement design phase of the product development, and planning of all inspection, and checking to ensure that the product or design meets the customer's end applications.

The organization must communicate with team to conduct detailed requirements of APQP and verify the implementation, and provide detailed for APQP status report. The quality planning should have managed to provide clear illustration of the task program and conclude associated risk during planning phase at the customer's specific request. Expectation from the quality planning element to carry out a risk assessment and specify the extent of his team participation in the advance quality planning processes.

The purpose of this element is to obtain inspection methods and used inspection equipment and tools which is adequate for the measuring works. The equipment & tools used for the inspection processes should be verified & evident of equipment capability, process suitability and requirements must have discussed with customers. The equipment & Tools are providing by planning team according to operation requirements. The inspection methods, equipment & tools used for inspection processes and inspection planning should be communicated with customers.

To secure the prototype quality, inspection plan carried out as the categorized and scope of the inspection and consistent inspection equipment for prototypes are defined and approved with customer. In case of customer having any special requirements or special characteristics should be included in inspection plan, and control plan and related documentation maintained and submission to customer accordingly.

To maintain customer schedules and dispatch the product, prototypes must meet quality requirements and cost competence. The expectations from this section is to proper planning, monitoring and inspection should be maintained & approved without any non-conformance with prototypes prior to delivery.

When we talk drawing and specification that means includes all the technical drawings and specifications, design data & information, material specifications received / provided by customers & prepared at supplier end. The element indicates the drawing and specifications and it related schedule management, generally customer must be informing to supplier of schedules and changes making in a drawing and specification on before real production to maintain schedule of product. If the supplier had prepared drawing & specifications, supplier responsible for agreed changes with customer.

If the customer provided all the design and specification, the supplier must assess the manufacturing feasibility of the products, from the planning stages to production processes. A supplier cross functional team is responsible for evaluate the manufacturing feasibility of the proposed product within the structure of the documentation / sales control review. The cross functional team must be committed that the product meet end application requirements and can produced, review, inspect, packed and shipped to the customer in time manner with expected quality.

A real production or mass production layout, or process flow chart of production is a visual representation of planned sequences of processes for particular product and its specification. The purpose of the establishment for planning, FMEA of process, quality control plan, production plan and visual data structure is to ensure that the process sequences of production stages and related, in-process, and incoming materials in production inspection.

A process FMEA is systematic procedures or method conducted for identify and account potential defects in production processes, and to analyze root causes to tracing real causes of defects occurred in processes. The method used before the product development, to prevent defects during process development. To get the better results all production and inspection stages should be involved for analyze. The PFMEA helps to detect potential defect modes, describe causes to easier for team to define necessary corrective measures and monitoring to evaluate control for appropriate location.

The purpose of this element is to maintain and improvement of the measuring system, capability study and inspection equipment accuracy. For the achieving the goal of the standard element requirement needs to conduct capability studies in direction to verify the suitability of the inspection equipment. The inspection and measurement methods should be verified & approved by customers for appropriate requirements, in case of the any modification are made in measurement equipment of method of inspection, it is necessary to capability study must be conducted.

It is important that the process & product specification requirements should meet during the pre-production, to achieve the standard specification needs to increase inspection frequency and additional inspection characteristics. All the inspection equipment, inspection methods and it scope should defined and approved by customer before the production start.

The process instruction is one of the important documents for the maintain and improve product quality & increase performance of appropriate site, all the instruction like production plan, work instructions, maintenance plan and schedules, process parameters etc., are used at the workplace should be easier for each people working at appropriate location, and should be accessible.

The purpose of the process is to ensure that the delivery capability in the contract or agreement with the relevant customer communication. In the concept all the logistics including packaging materials should be used suitable and maintain quality of product during logistics. The packaging specifications and corrosion protection for shipments to the customer, packaging specifications must be observed & approved by customer.

The purpose of the process is to verify of the mass production process. The advanced production quality planning expecting from this element is to use of machinery, tools, inspection equipment and location and manpower managed accordingly. In the production first trial, process & product verification of product quality as per planned, and the product quality must consist of each batch measurements as per standards.

To ensure that mass production i.e. samples collected from production are met the product & process specification requirements. Inspection related processes, methods, inspection equipment etc., should be documented and verified, approved by customer.

To ensure the product can be manufactured as requirement of product and process specifications are prove by process capability studies. The process capability study uses statistical method to prove of process is capable, to standard requirements of process & processes i.e. specifications. In the initial process capability study all the required pp/ppk values, machine capability at cm/cmk values should be maintained and controlled, in case of values or deviation identified that corrective measures must be introduced in order to achieve process capability.

The process verification is structural planning document prove that the product meets customer requirements and all the technical requirements are conducted through technical test with product from the production trial run, if defined in the design verification plan / or in product - process specification.

Initial sampling inspection is process that prove the product manufactured under the production condition meets the customer's requirements as well as customer provided technical, product & process specifications. In the sampling inspection, qualified inspector collects the samples from running production lines and inspect the sample according to standards and specification requirements.

Key Document:

| Status | Meaning |

|---|---|

| Green |

|

| Yellow |

|

| Red |

|

Conclusion:

To implement APQP in organization needs to establish cross functional team and define the responsibility to each member for implementing standard procedures of APQP is to assure that a product satisfies the customers. As standard practice top management is only responsible for assignment of responsibility to a cross functional team (CFT) with the involvement of more than just the single department. The cross functional team shall be satisfied that the proposed design can be manufactured, assembled, packed and delivered in sufficient quantity at an acceptable cost to the customer on schedule. CFT develop a timing plan based on the type of product, complexity and customer expectations through product quality planning timing chart. The outcomes from APQP helps to analyze that the product & manufacturing processes validated with respect to customer requirement.