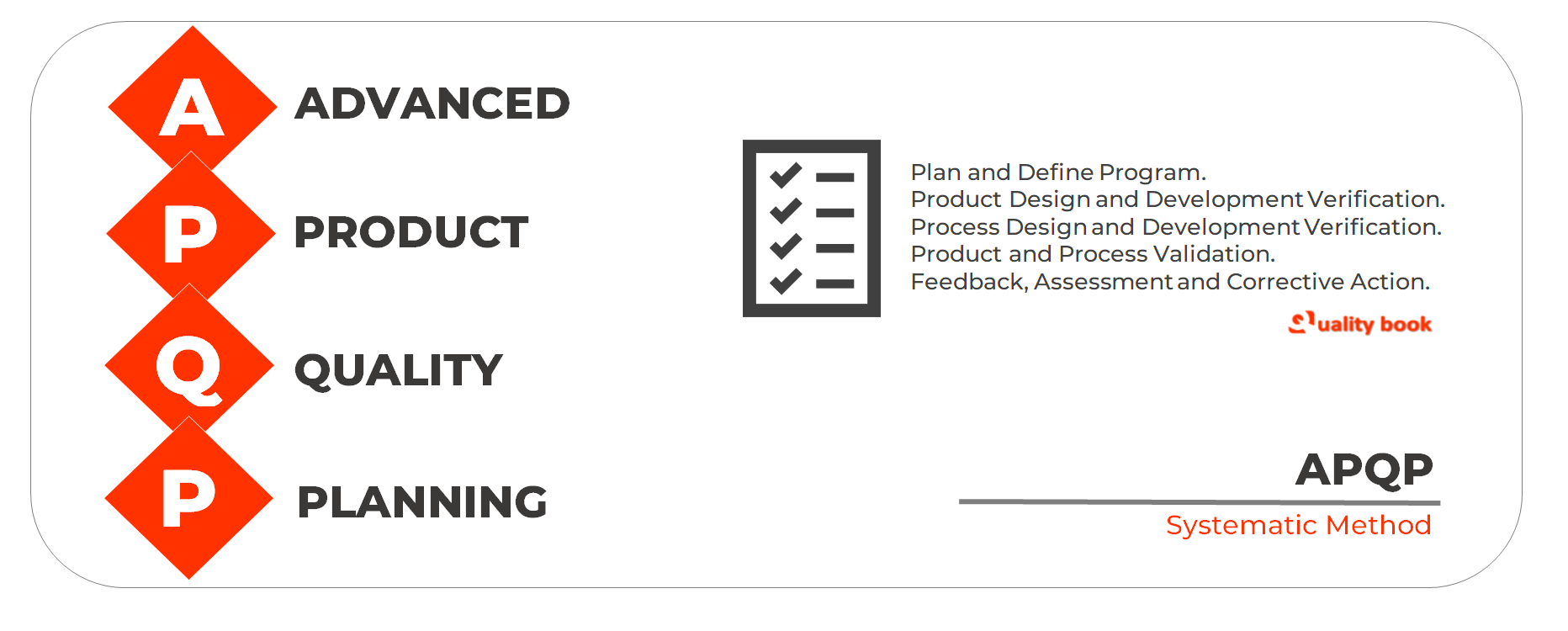

The abbreviation APQP stands for Advanced Product Quality Planning, which is a widely used systematic method to plan quality up front, in order to fulfil customer requirements. To reach customer satisfaction. APQP is not only a method. But also a structured framework, which defines exact steps to reach the serial production of a product in time, without risks, quality failures, delayed changes and unexpected costs.

The APQP manual was being developed by the big three US carmakers (Chrysler, Ford, General Motors) for years before its first release in 1994, published by AIAG, to provide guidelines to suppliers and sub-contractors in the automotive business. It is in close relation to various procedures, practices, quality tools, and analytical techniques, such as FMEA, SPC, PPAP, MSA, and follows the PDCA methodology.

As APQP was developed by automakers, it is mostly widespread in the automotive industry, however the framework itself was usable by many other industry sectors, and had been adapted by companies in sectors such as information technology, consumer goods, aerospace, etc.

Sections

In order to realize products with flawless quality, not only the process, but the product design must be robust as well by all means. Keeping this in mind, the APQP process contains five major sections (also called phases):

- Plan and Define Program.

- Product Design and Development Verification.

- Process Design and Development Verification.

- Product and Process Validation.

- Feedback, Assessment and Corrective Action.

Going from concept to product launch, each section of APQP is ending with an evaluation meeting (also called quality gates), when the team and the steering committee evaluates the actual condition of the relevant activities in the given phase. These activities are:

- Planning

- Product Design and Development

- Process Design and Development

- Product and Process Validation

- Production

To avoid misunderstandings, the sections and activities of APQP are two different terms. Section (or phase) means a given frame, divided by quality gates, while activities can be concurrent, overlapping sections (e.g. there is a time-frame, when both product and process development are running, while feedback and assessment are covering the whole APQP process). This also means collaboration between design, manufacturing and quality engineers (in other words: Simultaneous Engineering).

The following table represents the APQP phases and outputs:

The APQP Phases and Elements | |

| APQP phase / section | Elements / Points (AIAG APQP manual) |

| Plan and Define Program | INPUTS: Voice of customer Business Plan / Strategy Product / Process Benchmark Data Product / Process Assumptions Product Reliability Studies Customer Inputs |

| Design Goals | |

| Reliability and Quality Goals | |

| Preliminary Bill of Material | |

| Preliminary Process Flow Chart | |

| Preliminary Listing of Special Product and Process Characteristics | |

| Product Assurance Plan | |

| Management Support | |

Quality gate 1 | Preparation approval by the Steering committee |

| Product Design and Development Verification | Design Failure Mode and Effect Analysis (DFMEA) |

| Design for Manufacturability and Assembly | |

| Design Verification | |

| Design Reviews | |

| Prototype Build | |

| Engineering Drawings | |

| Engineering Specifications | |

| Material Specifications | |

| Drawing and Specification Changes | |

| New Equipment, Tooling and Facilities Requirements | |

| Special Product and Process Characteristics | |

| Prototype Control Plan (CP) | |

| Gages / Testing Equipment Requirements | |

| Team Feasibility Commitment & Management Support | |

Quality gate 2 | Prototype approval by the Steering committee |

| Process Design and Development Verification | Packaging Standards |

| Product / Process Quality System Review | |

| Process Flow Chart | |

| Floor Plan Layout | |

| Characteristics Matrix | |

| Process Failure Mode and Effect Analysis (PFMEA) | |

| Pre-launch Control Plan (CP) | |

| Process Instructions | |

| Measurement System Analysis (MSA) Plan | |

| Preliminary Process Capability Study Plan | |

| Packaging Specifications | |

| Management Support | |

Quality gate 3 | Pilot approval by the Steering committee |

| Product and Process Validation | Production Trial Run |

| Measurement Systems Evaluation | |

| Preliminary Process Capability Study | |

| Production Part Approval | |

| Production Validation Testing | |

| Packaging Evaluation | |

| Production Control Plan (CP) | |

| Quality Management Sign-off and Management Support | |

Quality gate 4 | Serial approval by the Steering committee |

| Serial phase | Reduced Variation |

| Customer Satisfaction | |

| Delivery and Service | |

Although the AIAG APQP manual defines APQP elements and project milestones in a logical and systematic way, many companies defined a very similar, but slightly different structure of the Product Engineering / Development Process (PEP / PDP). The whole process is divided into sections, but it contains many overlapping and iterations from development and realization point of view, based on PDCA and DMAIC principles:

A brief summary of the Product Engineering Process (PEP) | |

| Phases and Quality Gates | Elements / Points |

| Project Kick-off | |

| Phase 1 – Preparation and planning of project (pre-development) | Customer requirements and latent needs, preliminary special characteristics |

| Definition of product functions, Quantitative customer requirements, QFD (Quality Function Deployment) for requirements to functions | |

| Feasibility studies, Analysis of new technologies | |

| Sketches and drafts, Rough mechanical and electrical concepts (CAD / CAM, GD&T;, etc.) | |

| Design of system and system elements, Cost estimation | |

| Design of rough processes, Revised cost estimation | |

Quality Management Gate 1 (milestone) | |

| Phase 2 – Product / Process concept | Design concepts (selection of concept) |

| Specifications, Special product characteristics, Safety requirements | |

| Manufacturability (producibility) evaluation | |

| Test planning concept, Testing and diagnostic specifications | |

| Cost assessment for possible quotation | |

| DRBFM, DFMEA, QFD for system level | |

| Process parameter and product characteristic cause-effect relationship, QFD for process level | |

| Functional safety analysis | |

| Concept for draft PFMEA and prototype CP (Control Plan), Production layout, Lean and VSD (Value Stream Design) | |

| Selection of supplied parts / components | |

Quality Management Gate 2 (milestone) | |

| Phase 3 – Product / Process development | Finalized design and raw materials |

| CAD / CAM design (for series parts and components), Verified product safety concept | |

| Update DFMEA, DRBFM, QFD for process level | |

| Production process planning, Production line design, PFMEA, Pre-series CP | |

| Prototype production (B-samples) | |

| Prototype testing plan with DoE (Design of Experiments) principles | |

| Prototype testing and validation, Released production parameters, Product design freeze | |

| Series BOM (Bill of Materials) | |

Quality Management Gate 3 (milestone) | |

| Phase 4 – Product / Process realization | Production line setup, Capability studies (Cmk), MSA (Measurement System Analysis) |

| PTR (Production Trial Runs), Production of C-samples | |

| Creation of DV (Design Validation) plan with DoE principles | |

| DV test on C-samples together with the customer in series conditions | |

| Final product release | |

| Activate change management (for process and product design) | |

| Reliability testing and product audit plans | |

| Finalized processes, Packaging specification | |

| Production process release, Run at Rate (evidence of production capability), Series CP and testing | |

| Production of 0-series builds (D-samples), ISIR submission (AIAG PPAP or VDA PPF) | |

| Customer release, SOP (Start of Production), SOD (Start of Delivery) | |

Quality Management Gate 4 (milestone) | |

| Phase 5 – Serial phase and production ramp-up | Customer care, Warranty support, Claim management |

| Frequent product audits | |

| Ramp-up quality assurance (increased testing) | |

| Lessons learned (product / project) | |

The benefits of APQP are comprehensive, providing quality, prestige and last but not least financial advantages:

- On time serial production of a quality product with long-term reliability.

- Increases prestige and reputation of the company among customers.

- Sets quality planning into a systematic frame.

- Minimizes design risks.

- Minimizes process risks.

- Bundles the resources and directs them towards the project goal.

- Helps to avoid quality issues, thus reducing unexpected costs.

Suggestions

APQP is a key sub-frame of the Project Management process. While PM covers the whole project with all its elements, APQP does the same with all the quality related points. In order to reach the risk, and failure free manufacturing condition, the APQP team must work in structure.

Focus on finding the risks and potential failures up front. The earlier the team finds them, the less resource you have to spend on them.

Design freeze (the time after no design change is allowed) is a very crucial milestone. Defining its date is essential, and the needed amount of time must be spent on effective testing. Design verification can save you from plenty of headaches, money, and you won’t lose face.

Use lessons learned (LL) databases even if the subject of a new project is not very similar to a previous product. The experience of the past can help a lot!

Conclusion

- APQP stands for Advanced Product Quality Planning, and it is a widely used, systematic method to plan quality up front, in order to fulfil customer requirements and to reach customer satisfaction.

- APQP is not only a method, but also a structured framework, which defines exact steps to reach the serial production of a product in time, without risks, quality failures, late changes and unexpected costs.

- The APQP manual was first published in 1994 by AIAG, and has been developed by Chrysler, Ford and General Motors.

- A proper APQP process provides quality, prestige and financial advantages.