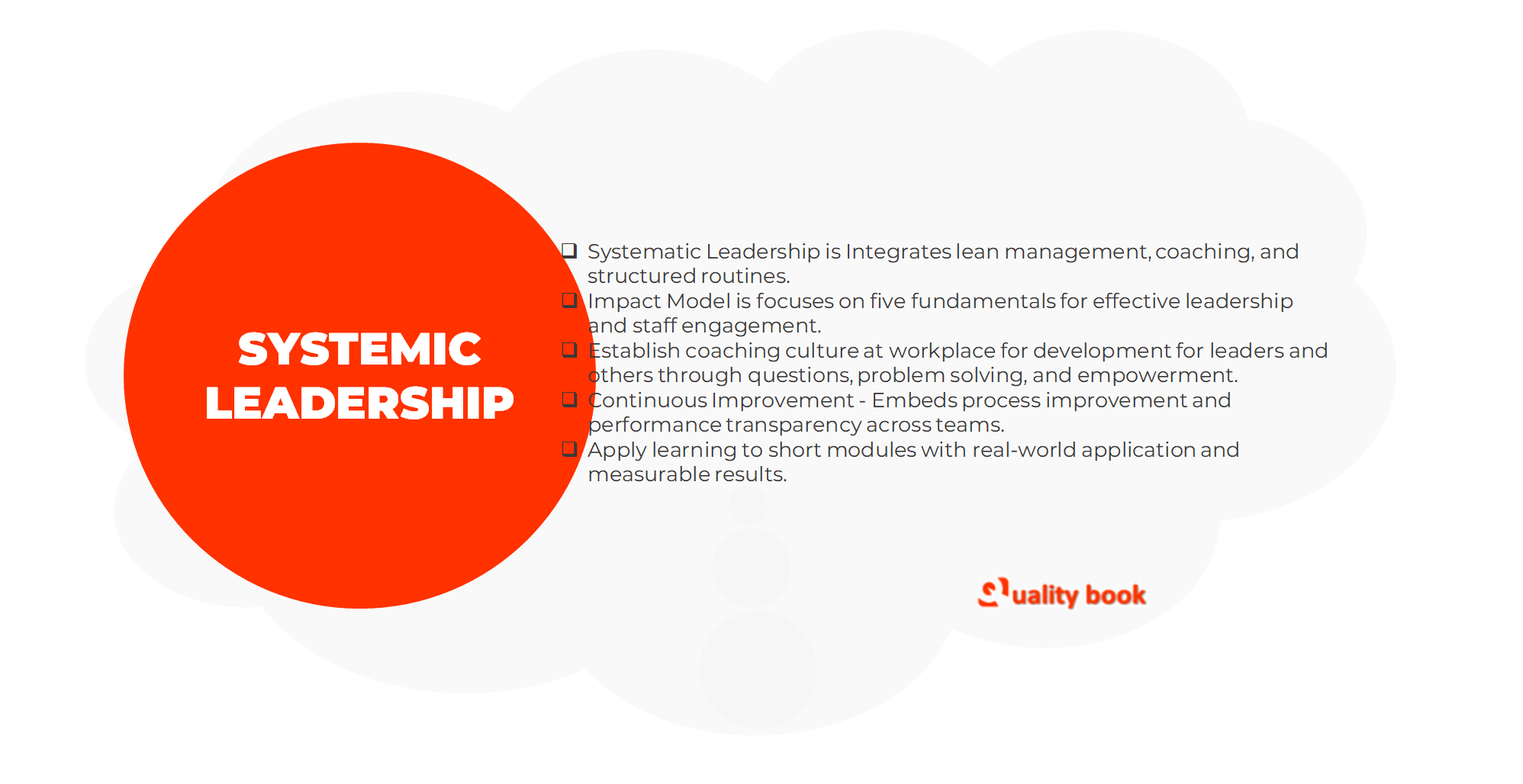

Systemic Leadership is a practical approach, to empower teams to achieve sustainable improvement of overall performance of business.

- Systematic Leadership is Integrates lean management, coaching, and structure routines.

- Impact Model is focuses on five fundamentals for effective leadership and staff engagement.

- Establish coaching culture at workplace for development for leaders and others through questions, problem solving, and empowerment.

- Continuous Improvement – Embeds process improvement and performance transparency across teams.

- Apply learning to short modules with real-world application and measurable results.

In the organizations want to be more effective and competitive, learning business improvement techniques such as lean and six sigma to achieve operational and performance excellence. Their managers spend long hours firefighting, fixing problems and trying to implement business improvement strategies, but knowledge, time, personal effort and upheaval don’t guarantee results.

We often find that organizations focus heavily on the tools and techniques, without giving thought to the leadership style, lean management fundamentals and practice necessary for implementing this kind of cultural change.

I am continually seeing the difficulties many organizations and managers face in sustaining their lean initiatives, so much that ten years ago I determine to create a lean management program that would enable managers to understand and succeed in leading and influencing lean practices through systemizing their activities and coaching staff.

The program was designed around systemizing leadership and management practices, incorporating lean thinking, lean management routines, systems thinking and neuro leadership. Our research and studies of management behavior, success psychology and optimal learning methods encourage us in the design and delivery in a number of successful leadership and management development programs across different business sectors over the last 10 years.

We identified a few core areas that managers must focus on to ensure they effectively engage and influence staff to generate a greater positive organizational impact. The IMPACT model focusses on integrating just five fundamentals alongside current management knowledge to ensure a practical, scientific and systemize approach to leading and managing in a transformational environment.

Those five fundamentals are:

A manager…

- is a coach and teacher, asking questions to enable thinking and self-reliance. This is the central fundamental, “leading with questions”;

- must apply, teach and demonstrate routine P.D.C.A. mind-set through daily practice;

- has to develop standard routines in their activity and staff engagement, including process assurance and performance management;

- leads and enables business and operational transparency. Performance, priorities, progress, issues and next step actions must all be clear;

- must ask questions leading problem solving through the development of others and not as the expert.

We found that when a manager understands and applies these fundamentals, they become highly influential and methodical in enabling effective problem solving and driving continuous process improvements, as well as, conveying the value of their people.

Essential to a lean leader’s role is creating an environment where people are value and enable with the opportunity to contribute and realize their own potential. Leading with systems, coaching, empowering and mobilizing people to think and develop their own effective ways to improve the business, guarantees the development of the next generation of successful leaders and value-added thinkers.

Modern Leadership

The program is evidence based and requires managers to demonstrate how they have applied the learning, its impact, and where they need support. The learning is performance evaluated and support by the individual’s line manager.

Modern leadership and lean management thinking must be base on the concept of adding more value.

The difficulty for many organizations is finding the right learning approach between the spectrums of individual and organizational development, whilst ensuring a balanced focus on both task delivery and people performance. The IMPACT leadership program achieves this balance through an applied learning approach, helping individuals and leadership teams reflect on their current style and realize the changes they need to make. Leaders are expose to styles of management which deliver more impacting and successful outcomes.

The purpose of this program is not to teach people how to manage, but to teach them a more effective way of managing and engaging with their workforce, to bring out the best from their people.

A Whole Company Approach

Having set the wheels in motion by training the executive team using the High Impact Leadership Program and in improving overall profitability and process efficiency, Patel mart was keen to mirror the benefits on the manufacturing side of the business across all business functions and other sites around the world.

“It had to be a whole company approach,” comments Dave. “We have now cascaded the program to around 150 leaders at Springfields and many more at our other sites in Sweden and the US facilities, which includes senior and middle management levels, and it was clear that the benefits of a systemic leadership approach in a lean environment were not only applicable to our manufacturing operations but could also enhance performance across all business functions.

Historically, there has been an expectation that any improvement in profitability had to be achieve through manufacturing efficiencies but, through the program, all departments have been challenged to incorporate strategy deployment and management coaching into everything they do, contextualizing how their actions are align to patel mart’s business breakthrough strategies and focusing on the role of individuals in delivering those strategies.

This program has now become one of our standards for Systemic leadership development at patel marts, and is part of our HPL (High Performing Leadership) ongoing program.”

Creating a problem-solving culture

A key part of the HPL Program is the coaching and teaching techniques all the leaders develop as part of their training and, using these coaching techniques to tap into the intelligence of the 1,200 people on site has been a significant part of the program’s success. “Following the program, we have done a lot of work around systemizing and standardizing our problem-solving approach,” Dave continues. “By routinely engaging with the workforce, providing them with a local problem and encouraging, even challenging them to think and explore about all the options for possible solutions they can apply, we have embedded problem solving as a company culture.”

Ongoing continuous improvement of the lean management learning process

The initial program left managers at patel mart with a more systemic and sustainable way of managing and improving business through competent problem solving and confident decision making. “Anecdotally we can see the many benefits to the business,” Dave explains, “but moving on and continually improving, we needs Lean Mentor International’s help in assessing the effectiveness of our new approach.” As a result, Lean Mentor International was invite back to carry out maturity assessments and a new series of workshops with the executive team to help develop a critical path for business improvement.

Neil Farley, Head of Business Transformation, has state “We are already, after just 2 years seeing significant changes and value from the program in terms of continual month on month improving trends and increase Operating Profit, with a decreasing manpower profile. We have also realize substantial site cost improvement plans, and unprecedent production output improvements, with the best output performance in one of our production facilities over the last year. Plus, we have had significant reductions in the cost of poor quality (COPQ) over the last 2 years.

Logically and systemically

All of these benefits, we believe are in some part down to improve focus and the coaching style of our leaders in helping staff in solving problems logically and systemically by all levels of the workforce, leading to improve individual performance and commitment. We know there will be other business benefits as our culture matures and the people take full ownership for developing those daily improvements so representative of a lean organization.”

Dave Williams adds: “We have identify what we want to achieve, what obstacles stand on our way and what we need to do to overcome those obstacles. From here, we will continue to assess the outcomes and address any gaps in our plans so that we can align our plans with our goals to achieve sustainable business improvement.”

“The program has been a complete success for us and we have applied many of the systems thinking and coaching techniques into our behavioral safety program also bringing significant benefits and improvements in safety performance.”

The power of this approach for patel mart has been in increasing the management value through transferring a lot of decision making, ownership for solving problems in a systemic way and wanting to make continuous improvements into the staff right through every level of the organization.

Continuous improvement culture

Most organizations know that developing a continuous improvement culture is much more than deploying lean tools and techniques, but many lack the insight and understanding of the changes in management behavior, routines and focus to really gain the benefits of a lean program. Working with Mick Gornall and Dave Williams at Springfields was an opportunity to directly influence the senior management team to help them see the value of leading with questions, having a systemic approach to their activities, especially around problem solving, and challenging their people to think for themselves.

The program was design around patel mart’s existing manufacturing system rollout and policy deployment process, so that it became business as usual and not a new initiative; this was important to enable continuity of the transformation, bringing about change as a result of an iterative management process. They already had many lean tools establish, but the workforce was continually waiting to be told what to do. Because the program was tailore to their systems, enabled their leaders to develop the systemic thinking capacity in their people.

Development of leaders and managers can be a challenge for a number of reasons.

- First, they think they have little time to attend three or even a five day development course. That keeps them away from business, even though it might be the right thing to do;

- Secondly, taking on board all the necessary information and remembering how to apply. It when they get back to the sharp end is almost impossible, especially when the real world of problems, challenges and daily urgency takes over.

- Finally you can’t really learn lean management practices away from the business, it has to be contextualize in real world results and practice in the business with self-reflection and ongoing support.

This is what makes this program so successful:

it was deliver in short, 1–2-day modules, with the learning building gradually and being apply over time. Each new module adding to the last to create an embed management style. That can be practice and improve between modules. Utilizing the A3 reporting process to self-reflect and commit to small improvements that can be measure.