Although Lean Kanban pull and push system than the MRP has a great advantage, but we cannot ignore the traditional limitations of the 10 manual Kanban, Kanban model are turning to the use of modern communications technology such as electronic billboards, Dynamic Signage flexible response to rapid changes.

Many of our business awareness of billboards there are certain errors that the billboards, is the factory, the department established within the message board, used to publish, such as production planning, team building, management objectives, plans and other information.

Of course, the message board is a lean visual management tool, but it and Kanban (kanban) is an entirely different concepts, kanban JIT production management on behalf of, an information delivery tool to pull the signal.

Generally, contain, material, address (where transport where), bulk and other information. Used to guide the production, shipping materials, procurement, in order to meet the former process (customer) needs.

I often come across some companies, learning the lean production or lean factory tour, you want to Kanban pull production plan to replace the process plan, but do not know the implementation of Kanban is conditional.

This paper is the analysis of the implementation of Kanban pull the conditions and limitations, its purpose is to make better use of Kanban techniques, improved signage, improved signage.

Traditional manual Kanban pull technology of the 10 limitations:

The kanban production as a precondition must be balance.

Kanban effective implementation is based on standardized, stable production cycle, the operation can be better. If the fluctuations in demand or production of unstable, with the billboards will need to adjust the number of sheets.

The products or parts must be reuse.

For re-use parts, signage is added after the pull-type production. If non-standard parts or custom products cannot use billboards, can pull the order plan.

The kanban-based inventory to hold the premise, not the zero inventory.

Kanban itself is standardized minimum package number, how to set and calculate the number of sheets Kanban itself is considered a dynamic safety stock.

If there are a lot of mixed breeds, it will set a lot of billboards in the scene, also there are a lot of inventory.

The manual Kanban with the movement of the articles must be manually recover.

Whether it is a single card or dual card system, require manual collection, especially the dual-card systems also need to pick up cards card exchange produced by the water spider (logistics workers) to coordinate, to bring the complexity of the scene.

If you use the computer system of electronic billboards, electronic billboards through the process before and after the bar code scanning to form a visual signage Figure empty or full, to automatically, quickly pull together the production.

Kanban information opaque, not long-distance sharing

Kanban information through a new position – the water spider (Logistics Industry) to coordinate. However, signage will need to purchase long-distance sharing Kanban with suppliers of information, which requires the supply chain to support Web electronic billboards.

Kanban card is easy to wear, loss, damage.

In practice, often see Kanban card wear, but have not seen it clearly. Kanban card size must also be designed to avoid loss and prevent pocket or hidden.

Set by hand Kanban, Kanban cannot calculate the number of sheets of dynamic simulation.

Production managers need to demand changes to the manual release Kanban number of sheets, it is difficult to adapt to changing needs, the number of sheets of the adjustment lag Kanban, Kanban cannot be dynamic simulation of the number of sheets.

Hand-detailed process Kanban cannot track the serial number of quality tracking data

Because the manual Kanban is recycle and cannot record the serial number and quality of tracking data.

Hand-kanban and ERP cannot be the financial cost of data integration.

We often see the warehouse keeper, before work, pick up billboards of the information collected by hand knocked into the ERP system, each unit of material, labor, fee and cost information will need to ERP information system for cost accounting.

Kanban production strategy is more difficult to adapt to the environment, especially the more variety, small batch, according to a single design, project manufacturing mode.

The condition is due to use of Kanban products or components must be reusable, so the Kanban production strategy more difficult to adapt to the environment, especially the more variety, small batch, according to a single design, project manufacturing mode.

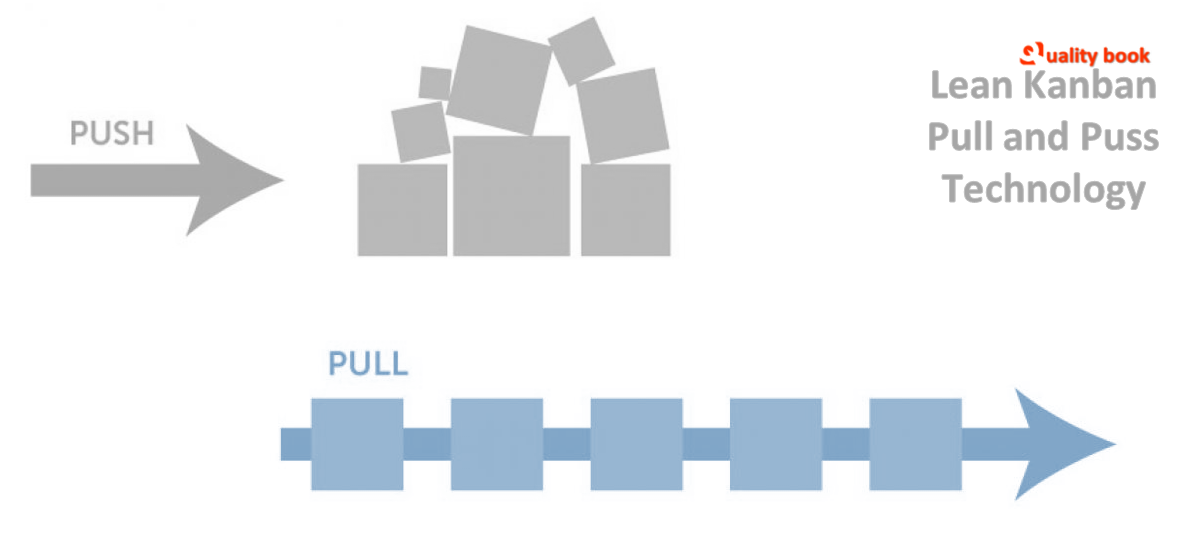

In short, I think that there is no 100% pull production. There is no 100% push-type production, must be consider according to the specific combination of push-pull ratio. This ratio can be consider different products or parts. You can also consider the process at different stages.

Traditional billboards should be replace by the computer age, electronic billboards. With dynamic signage to respond to change. IT Information technology allows more flexible lean production.

Of course, Lean Kanban is a tool in the implementation of lean production, the first of the current status of value stream analysis VSM, do to improve the flow, the flow cannot place on the layout to improve or SMED / TPM, it cannot flow where do Kanban pull. Kanban pull do not consider scheduling optimization.

Their common purpose is to shorten the delivery period, changing quickly to meet customer demand, reduce inventory, reduce costs, eliminate all waste, improve overall production efficiency.