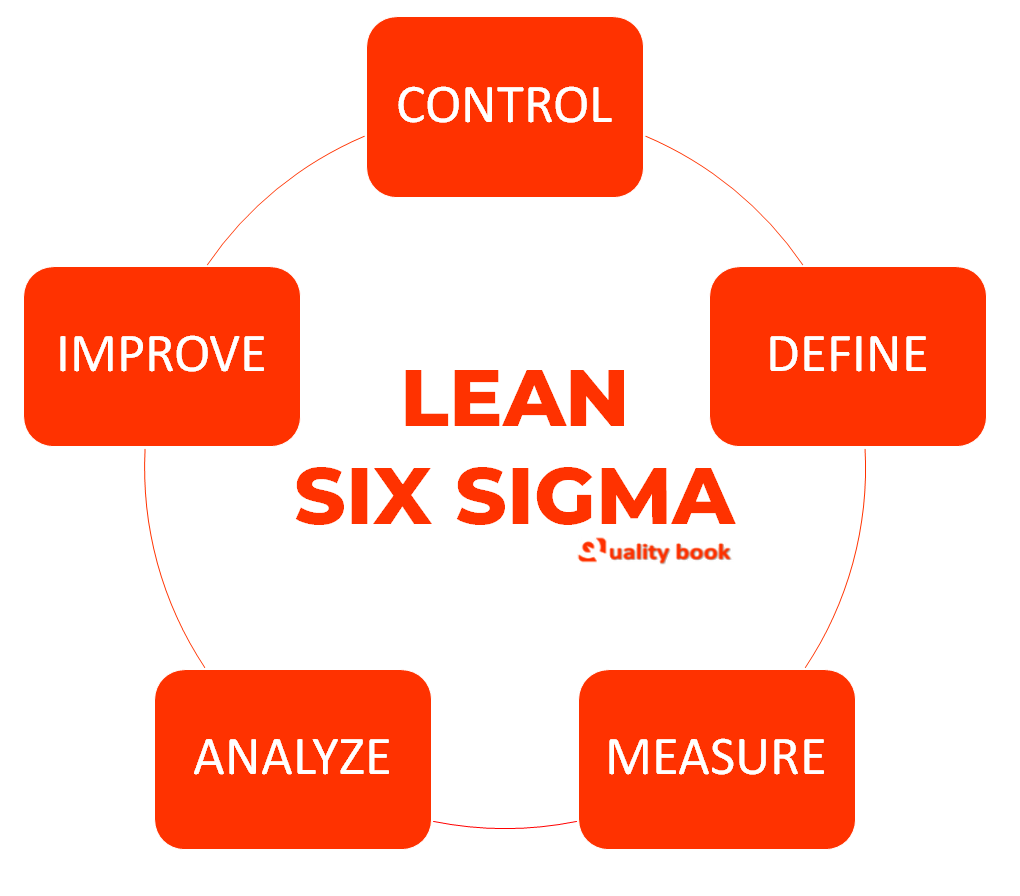

Lean Six Sigma some time fails due to a lack of stewardship. Such as lack of leadership with team work, and responsible execution.

It seems that everywhere I look – every article I read, every subject matter expert to whom I speak, and every talk to which I listen – The message appears to be the same: Lean six sigma fails.

Depending upon the source, lean six sigma initiatives might fail 25% of the time or even 70% of the time. Some even claim that it never fulfills its promise or realizes its potential.

In fact, there are so many articles and lectures on how often and how much lean six sigma fails that it is amazing anyone would even bother to try to implement it. Or otherwise select it as a path for improvement.

Investigating the Root Causes of Lean Six Sigma Failures

As a long-time member of the Institute of Industrial Engineers (IIE) and being on the Advisory Board of its Process Industries Division.

As well as being on the Advisory Board of Binghamton Universities System Science and Industrial Engineering (SSIE) Department.

I have been intimately expose to the material on the subject being taught and decide to investigate the “root cause” of such poor results being report. The increasingly poor expectations associates with continuous improvement initiatives.

During this exercise, and for both academia and industry from sources around the world. I examined the curriculum offered and reviewed the books and other materials used in the teaching of the disciplines associated with CI in general, and lean six sigma in specific. I also examined the websites and articles written by practitioners and consultancies (including my own).

Lean Six Sigma’s Focus on Tools and Vision Over Real Practice

Almost all of the material I read referred to the forensics of the disciplines – a focus on the “how”, including the “tools” of the trade and the “methods” of their leveraging and deployment. One book had an emphasis on 5S, another on VSM, kanban, kaizen, and so on.

Another book went at great lengths to talk about the importance of flow and roadmaps. And every book I read made some reference to the miracles performed at Toyota and advocated how they can be replicated in any business anywhere.

Which brings me to the other underlying theme that was shared in everything I read: the “why”.

All of the books and materials I have read and the lectures I have attended have discussed in great detail the benefits of embarking on such programs.

All of them create a vision of a better place – a better set of conditions under which a business might operate and the great benefits which will be realized as a result.

They all create a very compelling and pretty picture of what the world can be like if only we embrace the disciplines of lean six sigma as the approach for a CI program.

The Missing “We” in Continuous Improvement Efforts

All of this knowledge and instruction is necessary, well and good. I would support any argument that it is important to know how to properly use the tools in your toolbox.

Which one to grab under any given circumstance and how to wield it for maximum effectiveness. I would also support the vision paint by the proponents of what could be achieve.

But the one thing I noticed in almost all of the material I reviewed – very subtle in nature, but with a profound impact on the results – was that the consistent references to the singular.

There were many mentions of “you” and of “me” and of “I”, but very few to “we”, or to “us”.

It is almost as if any results that might be achieve in a continuous improvement program. These are solely the consequences of an individual’s efforts and not that of a team. Not to mention an entire company.

If leadership, program management, and communication skills are mention at all. They are usually given short shrift and tucked towards the back of the book.

The Missing Link Between Leadership and Practice: Stewardship

Maybe all of this is natural. There is an obvious distinction between being a “leader” and being a “practitioner”.

The leader mainly operates above the details and has a propensity to think strategically with sights set beyond the horizon.

Whereas the practitioner lives more in the here-and-now with an emphasis on training and experience that is more logistical and tactical in nature – the person who implements the strategy.

And perhaps this is why the material written about leadership does not delve deep into the requirement details of continuous improvement and lean six sigma.

The material written about continuous improvement and lean six sigma does not address the importance of effective leadership and the required skillsets.

In my opinion, herein lies the “root cause” of why CI and lean six sigma initiatives fail to realise their full potential. In a word, stewardship. Or in this case, the lack thereof.

Merriam-Webster defines “stewardship” as “the conducting, supervising, or managing of something; especially: the careful and responsible management of something entrusted to one’s care.”

Stewardship: The Bridge to Lean Six Sigma Success

Unlike leadership, which is remove from the details, and unlike being a practitioner. Which is all about the details, stewardship is a cross-over function that bridges the strategic, through the tactical to the logistical.

To be a steward, you must have something entrusted to your care – and you must be careful with, and responsible to, that which has been entrusted to you.

As a steward, you are not only “conducting”, as a practitioner would; you are also supervising and managing, as a leader would. And as a steward, you are not alone – but a member of the community over which you preside; a community that depends upon you as much as you depend upon it in order for both to be successful.

Which comes to my recommendation:

Believe that addressing the need for stewardship and teaching stewardship skills are critical to the success of any CI program. Stewardship establishes the necessary precursor environment only through which the full achievement of the benefits of any CI program is possible and will result in the realization of the maximum potential reward associated with leveraging the tools and methods of lean six sigma.

I also be live that the teaching of these stewardship skills should be move to the front of the curriculum and materials – and not as an elective or after-thought. As an individual member of the community – whether your role in a project or a business is that of a practitioner or that of a leader – the steward will ensure everyone is working as a team. And working as a team makes all the difference.