What is Kaizen?

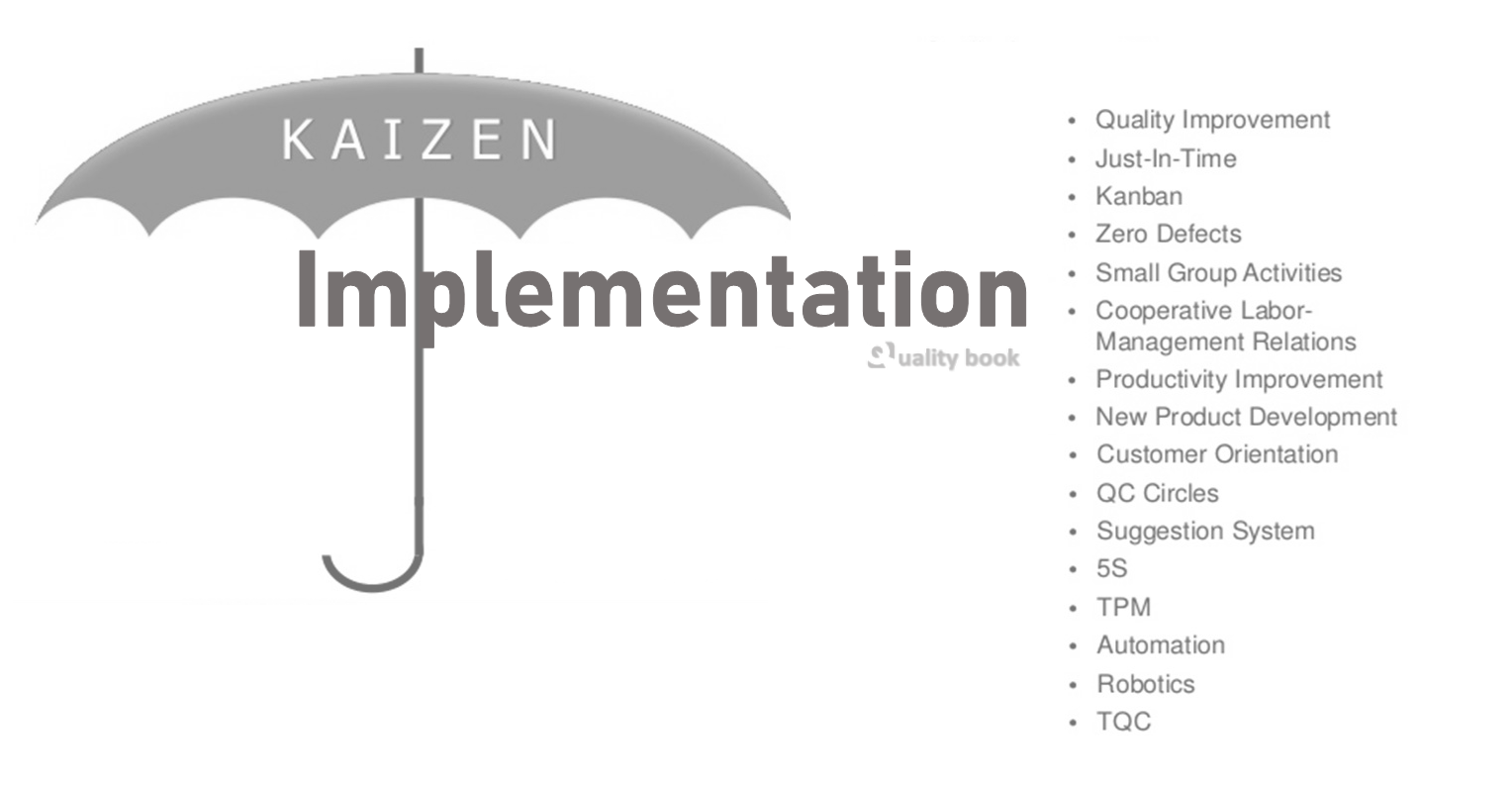

Kaizen (k-eye-Zin), define by the Japanese as “continuous incremental improvement”, is a fast and furious implementation of continuous improvement activities designed to create radical and sudden changes in business processes. During a week of highly focused activity, a cross-functional, section specific team receives training on specific tools and techniques needed to analyze and improve a process immediately. There are 10 key steps to this process, and they are:

10 steps of kaizen implementation:

- Training

- Project Selection

- Team Selection

- Value Stream Mapping

- Process Mapping

- Developing Baseline Data

- Creating Spaghetti Charts

- Conducting Time Study Analysis

- Developing Continuous Improvement

- Implementing Appropriate Changes

A key aspect of service organizations is the flow of information. In fact, a core process in any financial service organization is that information flow. There are many steps about which we have written on how to implement process improvement in service organizations. One of the most popular articles was “What About Lean in a Services Environment?”.

Lean, with its focus on identifying the Elements of Waste, is a powerful concept in a services organization. This article is meant to drive down one step further into using Kaizen events to eliminate said waste. But when it comes time to actually make improvement changes, Kaizen is one of the fastest and cumulatively most

impact activities a service organization can implement.

Training

The key issue is to select a small group of individuals to be trained as mentors who will also be the key person to select the team members.

Project Selection

We have written extensively about the need for projects to be aligned. A few of the articles are “Let Your Business Define Your Performance Improvement Program” and “Business Process Management (BPM) = Robust Project Pipelines After the Low Hanging Fruit is Harvested “. But along with alignment, project selections should be cognizant of the impact the project will have on the specific area in which the project is to be conducted as well as any up or downstream effects.

Team Selection

The team must start with subject matter experts from the targeted process’ area. But it should also be cross-functional and include process owners, finance & admin personnel, IT personnel and anyone who has pertinent knowledge of the project process. These people should be open minded, willing to challenge the status quo and influential in the organization.

Value Stream Mapping

This is a hands-on technique utilizing flow charting and icons to analyze information flow in graphical form. The team will identify and compile all the specific elements necessary to bring a service from inception to delivery. The purpose is to understand the relationship between process steps and identify those areas most in need of improvement.

Process Mapping

The process map is more focused on one part of the overall process than the value stream map discussed above and provides more detail. When a team builds a process map it allows everyone to agree on the actual steps perform to produce the product or service. It’s a great tool for identifying non-value-added process steps and reducing complexity. This begins the team’s root cause analysis.

Developing Baseline Data

You must develop Primary Metrics to improve a process. In fact, it is the development of that Primary Metric that often leads to and is an indication of improvement.

Creating Spaghetti Charts

This is a visual diagram depicting the information, personnel, and document movement in a process, department, or entire service organization. It is a great first step to eliminating waste in motion and conveyance.

Conducting Time Study Analysis

This tool is used to collect and verify cycle time data relative to an operation or process. This provides for careful study of each aspect of the process and continues to contribute to root cause analysis.

Developing Continuous Improvement

This is where the team records the changes to be implemented resulting from the analysis of collected data and brainstorming. The purpose is to identify improvements and their implementation.

Implementing Appropriate Changes

It seems all that is left is to implement the improvement. But along with implementation, the team should develop Control Plans so 30 to 60 days after implementation one can assess the impact of the process changes.

Service organizations are unique in their reliance on people and information, those two organizational elements are the service companies’ most valuable assets. One might say customer relationships are the most valuable asset but to a great extent. Those relationships are entrusting to those people and organizationally capture through information, if you are part of a service organization team and looking to drive improvement FAST, then look at the aforementioned 11 steps to implement kaizen implementation in a service company.