Six Sigma Methods (DMAIC & DFSS) may help you to drive process improvement, waste and defect reduction, as well as improve organization’s performance.

The Six Sigma methodologies

Six Sigma is a proven methodology aimed to improve the measurable results for all types of organizations, including nonprofit, manufacturing, government, service, healthcare, and research organizations. The Six Sigma methodology has to be introduced during the first phase of the deployment itself, so that improvement is obtained along with a generic problem-solving line of approach. The following are two important Six Sigma methodologies:

DMAIC

The DMAIC (Define-Measure-Analyze-Improve-Control) methodology of Six Sigma has the following 5 stages:

- Define – main project goals and current process

- Measure – vital aspects of current process and collection of relevant data

- Analyze – collected data for verifying cause-and-effect relationships

- Improve – the process on the basis of data analysis by employing various techniques

- Control – the process, to check for corrections in any deviations from target, so that defects are avoided.

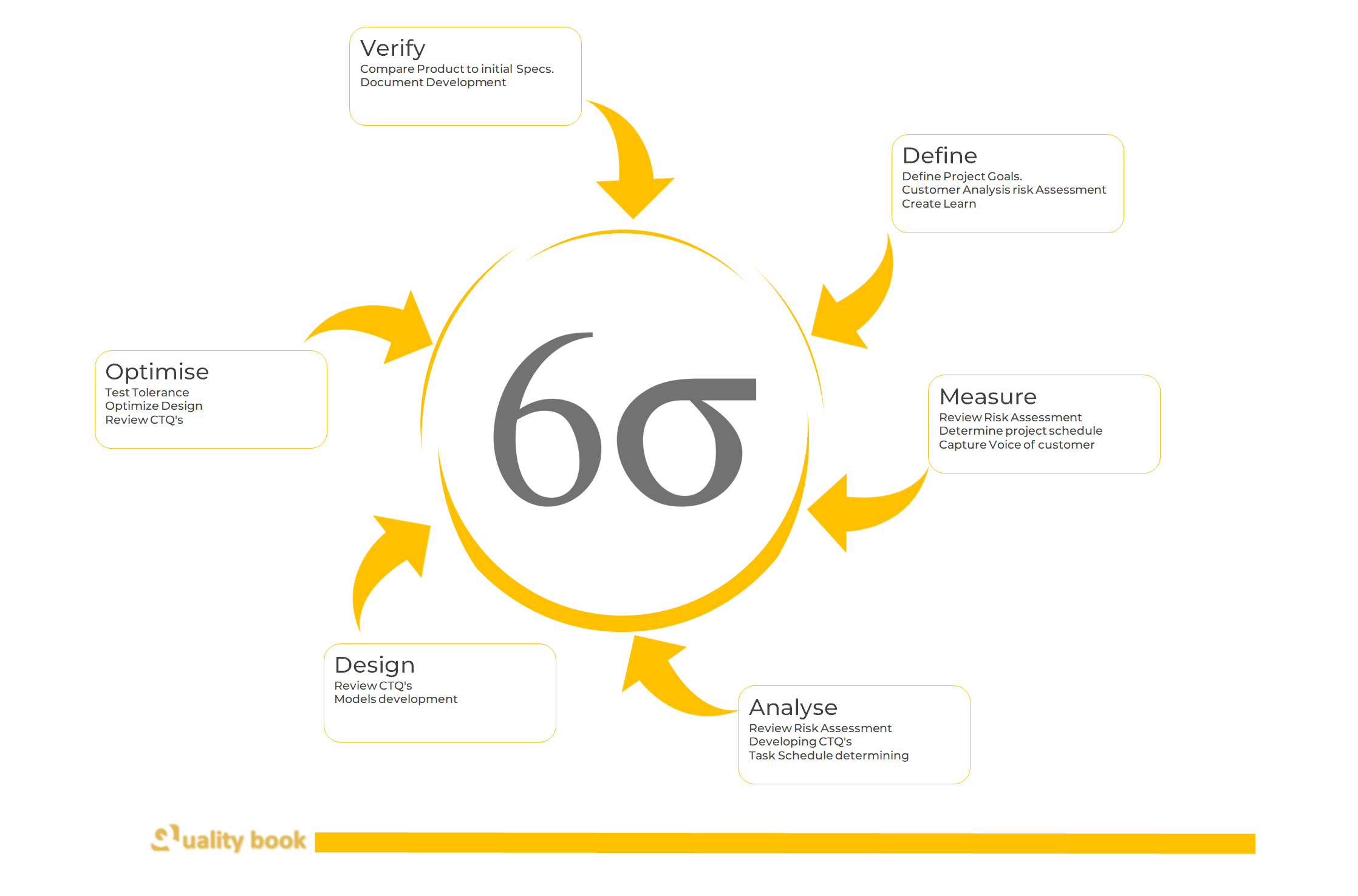

DFSS / DMADV

DFSS (Design For Six Sigma) focuses on developing defect-free products or services. It works on combining many tools used for improving existing products/services, and integrates customer voices and simulation methods for predicting new process and product performance. The DFSS/DMADV (Define-measure-Analyze-Design-Verify) methodology too has five stages:

- Define – design goals consistently to suit customer demands and organization strategy

- Measure – and identify product capabilities, CTQs (Critical To Quality characteristics), production process capability, and risks

- Analyze – development of alternative designs; creation of high-quality designs, and evaluation of the best design

- Design – optimization and plan for verification. Simulations may be required in this phase.

- Verify – design, arrange for pilot runs, production process implementation, and handing over of design to the process owners

These are the two important methodologies of Six Sigma. The training of Six Sigma is based on the five phases of DMAIC methodology. The time gap between each training session is utilized for application of tools that were learned previously.

Laws of Lean Six sigma

Six Sigma is a proven methodology aimed to improve the measurable results for all types of organizations, including nonprofit, manufacturing, government, service, healthcare, and research organizations. This methodology has to be introduced during the first phase of the deployment itself, so that improvement is obtained along with a generic problem-solving line of approach. Six Sigma focuses on the leadership-sponsored projects. DFSS (Design For Six Sigma) methodology deals with developing a new product or service that is defect-free. Then there is the DMADV (Define-Measure-Analyze-Design-Verify) project methodology in Six Sigma.

- Many people confuse the methodologies of Lean and Six Sigma. Though there are many similarities, it is necessary to draw a comparison between Six Sigma and Lean, so as to understand Six Sigma better.

- Focus – The focus of Six Sigma is on reduction of variations and improvement of process yield by implementing a problem-solving approach. Lean, on the other hand, focuses on optimization of the process flow and reduction of waste.

- Training – The entire process of Six Sigma training is broken down into five distinct phases of DMAIC (Define-Measure-Analyze-Improve-Control) process. The time gap between each training session is utilized for application of tools that were learned previously. On the other hand, Lean training is the combination of short training sessions on the principles and practical application on the shop floor.

- Duration – Six Sigma projects require duration of few months. On the other hand, Lean projects could be completed in a couple of days.

The two well-known Six Sigma certifications are the Green Belt and the Black Belt. And then you can go for the Master Black Belt Certification, which is the mastery over Six Sigma methodology. The Six Sigma methodology could be used in combination with Lean to have a competitive edge over others.