Over the past few years, businesses have become conscious of increasing customer satisfaction and delivering quality products. Therefore, a lot of competition is being created in the market, so that it has become necessary for the businessmen to fully understand that the customer has paid more attention to the quality-critical characteristics to give complete satisfaction to the customer. So, for businesses “Critical to Quality (CTQ)” becomes a useful tool for customer needs. So, what is this critical to quality (CTQ)? Understand that!

What is Critical to Quality (CTQ)?

To understand the quality of goods sold to customers we must consider the customer’s end-product and related process parameters. Emphasis is placed on excellent “critical to quality” to focus on requirements that are identified as important by the customer. This makes it easier to identify the determinants of quality criteria, which present a complete picture of what is actually important and relevant to the customer.

Hence the voice of the customer, which allows us to directly understand the customer’s needs, preferences, and end application requirements. Which can be known from general data and analysis.

“Critical to quality is a tool for understanding what is important as quality from the customer’s point of view, as well as what is relevant to the product, with end-product parameters that meet quality criteria.”

When you are going to create new product for the business, the CTQ is much important tool that make you surprisingly provides measurable information that help you to met the critical needs of the customers. The Critical to Quality Tree is one of the important tools that helps to business for analyzing the requirements of the customers which are measurable and associated with the target product.

An important tool for addressing customer requirements is the CTQ tree. This can be use to determine where the driving force lies behind the characteristics available to the business, and it becomes easy to prepare the product according to the needs of the customers.

Critical to Quality Tree

It is a tool, whose visual shape resembles a tree. Through which, based on the information receiving from the customer, what do customers really want? and what do customers need for their processes? This can be use to identify it.

Understanding customer needs – First it is necessary to understand quality from the customer’s point of view based on product characteristics. Using a critical to quality (CTQ) tree, a business can determine the product characteristics and perform the necessary quality measures.

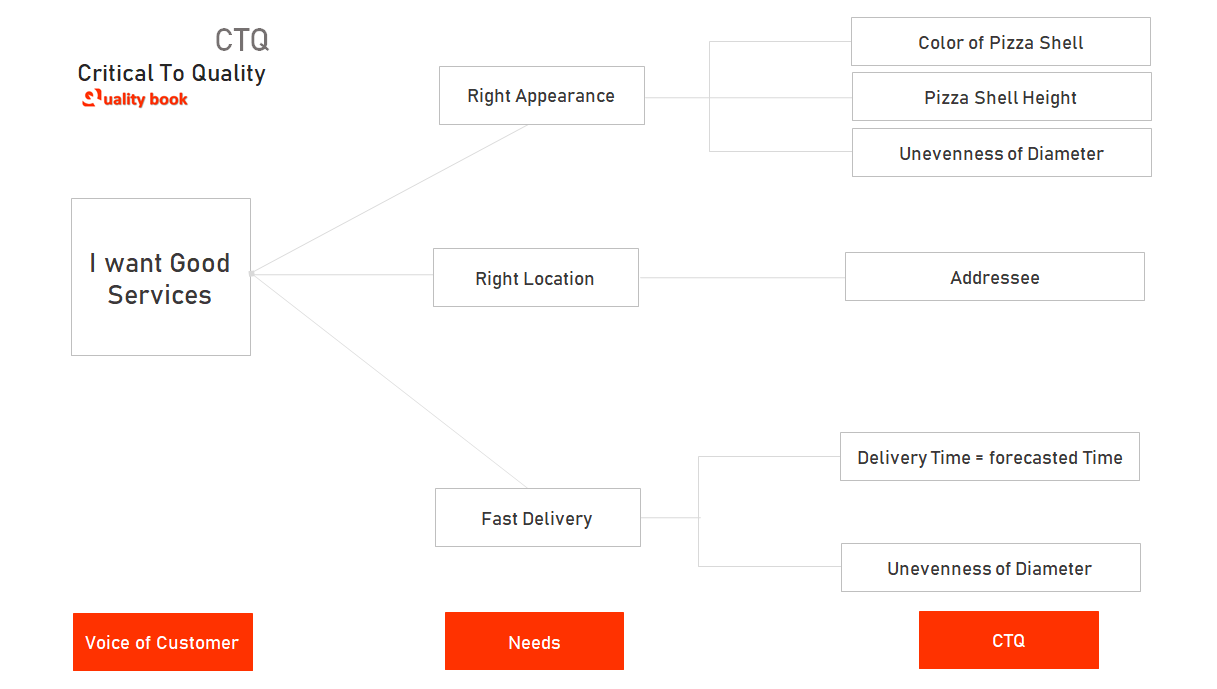

As you can see in the picture above, this is a content diagram, which looks like a horizontal tree, with branches displaying all the necessary information across it. It is actually a visualization tool that captures a collection of state or imply expectations of the customer. The real purpose of CTQ is to inform the changing broad needs of the customer, often those needs are also transforms into more specific ones, while at the same time defining the waiting time of the buyer among the critical indicator characteristics for quality.

The Critical to Quality (CTQ) has three main components. Which is Voice of Customer, Needs and CTQ. In the first component you can understand what the customer wants? from the second component you can understand what are the requirements demanding by the customer? and from this second component it is understood that the actual needs that make the customer’s needs effective.

What action to take based on CTQ tree?

From the CTQ tree it can be understood, what are the needs of the customers, and based on that what are the basic characteristics of the product that the customers want. But to produce a product with such characteristics. The capabilities of the processes have to be precisely calculated. Also, by removing defects in production processes (which are unnecessary for the customer), production costs can also be reduce.

Start with customer requirements

First we have to understand the needs of the customer, if we want to find the defects in the processes easily. Through the “Voice of Customer” the primary data obtaining and the problems associates with the results can be translate through the CTQ.

Defects (unnecessary processes, product features or other defects – from the customer’s point of view)

Defects here do not mean that the product is broke or other technical defect. Defect here means unnecessary for the customer.

Eg – “A customer wants coffee without cream”. Then cream is unnecessary for him, or coffee cannot satisfy him in which the shopkeeper has put cream in the coffee without asking.

In short, a defect in which the product does not meet the customer’s requirements, or does not meet the functional or physical requirements.

A unit of production

A product unit is something that a customer can measure. So a business process should have a measurable and observable outcome. A result can either be a physical unit such as a process with a beginning and an end in the case of a product.

Identify opportunities for defects

Simply put, opportunities are the total number of possible opportunities for defects per product unit. Each of which possibilities must be independent of other possibilities. Also, as a unit, should be measurable and observable. Finally, feasibility is directly related to quality-critical characteristics. The total number of opportunities indicates the complexity of the product or service.

Worth knowing:

Always remember, never understand the customer’s needs based on guesswork or imagination. Ask customers, understand, re-understand if not understood, check the information receive, construct a CTQ tree and display the information at each level, so that small and large defects, accurate information and original expectations can be identified.