Lessons learned (LL) is a quality principle and a quality tool in one. On one side. The lessons learned process supports quality improvement, besides, it also means a systematic approach in order to ensure the transfer of all relevant experience and knowledge to the quality planning of future projects. It focuses on eliminating potential issues that were identified in the past; thus, it is an essential part of continual improvement, and project management.

(Remark: “Lessons Learned” is mostly used in North America, while “Lessons Learnt” is much more common in British English).

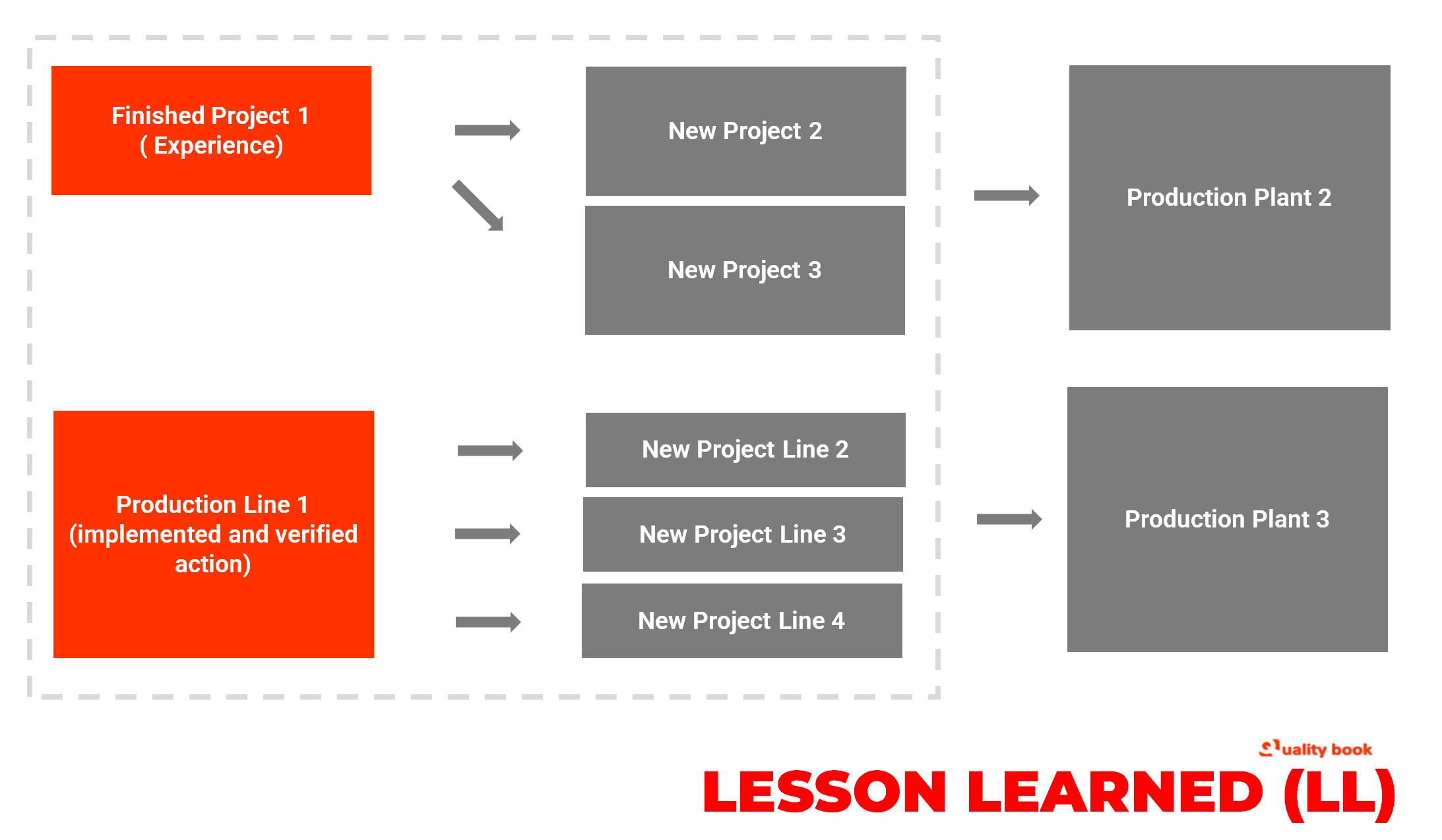

During a lesson learned procedure, the organization identifies, logs and transfers knowledge and past experience in time and space, for example:

- Transferring design experience of a high-running product into the NPI (new product initiation) process of a new product, by identifying design gaps and the working solutions.

- A manufacturing process step of line A is improved, and this knowledge is transferred to line B and C.

- A successful quality improvement project is spread to other facilities, plants.

Project & LL

As part of TQM (Total Quality Management), LL is preventive, and it is able to maintain a systematic improvement only by doing it right. It affects manufacturing and also related supporting processes, new projects.

What are the trigger points of lessons learned:

- New project (LL provides information, gaps, barriers, and the best solutions from the previous similar projects).

- New product initiation (LL gives information, design knowledge, manufacturability, and process knowledge about previous products, that are similar enough to be comparable).

- Quality issue (LL provides not only a systematic summary of a similar issue, but also the solution. If done right, 8D reports also contain LL in step D7, as part of preventive actions).

- Transfer of beneficial improvement (LL can be used to successfully transfer process improvement knowledge to other manufacturing lines, departments, plants and even divisions).

There is no working LL without collaboration and cooperation in the organization. LL only makes sense, if it is applied continuously, and the experience and solutions are adopted by stakeholders.

LL System

In order to have a usable LL framework in the company, implementation of LL systems is advisable. What are the features and advantages of a properly working LL system:

- It provides information to those who really need the information (no unnecessary information flow).

>Example: when a product designer of printed circuit boards shares a LL case study. The system forwards it to other designers, who are working on similar products. In order to reach the required result, LL groups need to be identified correctly. - The system is ergonomic and forces the users to summarize the LL study as much as possible.

>Example: the company uses an online form for sharing LL. Which can be formed to the purpose, based on the needs of the organization. In addition, if the system is not user friendly and ergonomic. The stakeholders will consider it as a barrier and not an aid. - Not only are the experienced and recognized problems described, but also the solution.

>Example: many LL users make a mistake. When they only share what they found, instead of giving the available solution to the others. A lesson learned is not a lesson learned without the solution!

Conclusion

- LL stand for Lessons Learned.

- LL is a systematic quality principle and preventive tool.

- Lessons learned focuses on transferring the experience and knowledge of previous projects / products to new ones.

- When done right, LL can maintain continuous improvement, and the prevention of potential failures and issues.