Overall Equipment Effectiveness is a productivity metric, containing quality related factors that truly affect the effectiveness of manufacturing machines and processes. The metric represents the ratio of good output vs the theoretical good output. 100% OEE means, that we produce only good parts without downtime, at the required maximum speed.

OEE stands for Overall Equipment Effectiveness. OEE is a universally accepted set of metrics, used by manufacturing entities.

The principles of OEE were deployed in 1982 by Seiichi Nakajima, as part of the TPM concept (Total Productive Maintenance or Total Productive Manufacturing). During the 80’s and 90’s, OEE conquered the World, spreading among multinational companies. Even after the year of 2000, an extensive literature of OEE evolved, thanks to experts and pioneers.

Properly implementing OEE in a manufacturing environment provides many benefits, such as:

- Maximizing capital utilization and competitiveness.

- Tracking the progress of “waste” elimination and the improvement of good output.

- Comparison of performance (line vs line, line vs plant average, plant vs plant, company vs company, etc.).

OEE Factors

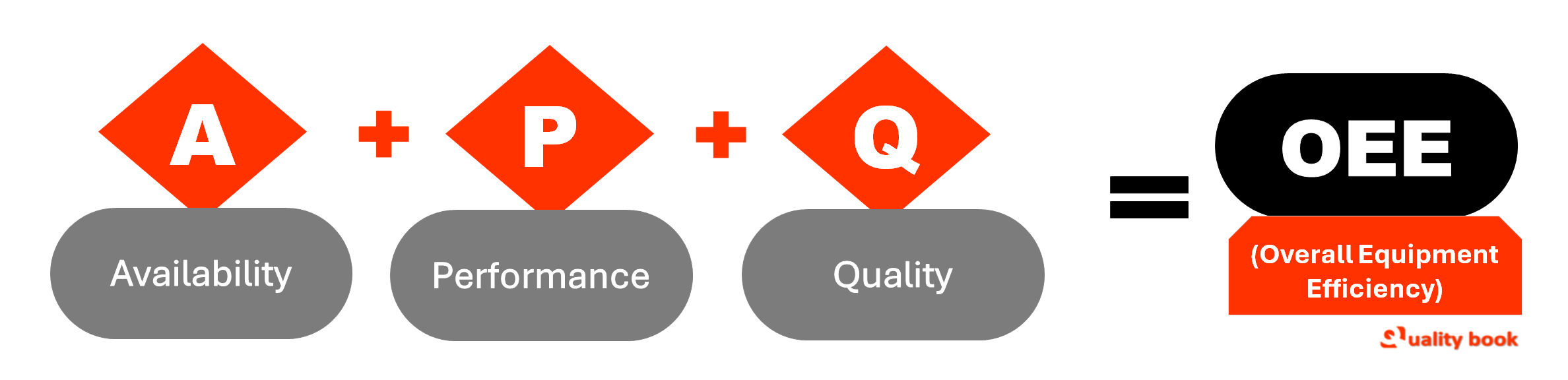

The general concept of measuring manufacturing performance or effectiveness holds two major and four minor metrics. The major metrics (OEE and TEEP) rely on the minor ones (Loading, Availability, Performance and Quality).

The most commonly used metric among the major ones is the OEE, which is the multiplication of three minor metrics: Availability, Performance and Quality. Having known these three metrics, we are able to map the landscape of losses and waste, thus we can focus on the bottlenecks and improve the major causes. When we create the OEE mapping, we can clearly see the differences between the actual output, and the theoretical maximum capacity.

OEE measures the effect of “6 big losses“, which reduce our OEE score. Each two losses can be directly linked to the availability, performance and quality metrics.

| The factors of OEE | ||

| OEE factors | Big Losses | Examples |

| Availability | Down time due to breakdown | Machine malfunction, reactive maintenance |

| Down time due to adjustments | Lack of material (waiting for raw materials), change-over to another part number | |

| Performance | Speed loss due to small stops | Blocked material feeder, jammed conveyor |

| Speed loss due to reduced speed | Worn equipment, decreased machine capacity compared to machine specification | |

| Quality | Quality loss during start-up | Scrap, rework, retest (of those parts that are built during line start-up), expiry of materials (e.g. drying of glue) |

| Quality loss during normal production | Scrap, rework, retest (of those parts that are built during standard operation) | |

Availability:

The metric shows the ratio of actual production time and potential (planned) production time in percentage. If the machine operates full time compared to the maximum of the given shift / day / month / etc., the rate is 100%.

Availability = Actual Production Time / Potential Production Time * 100%

Performance:

This metric provides the speed of the machine, represented by the ratio of actual output, and potential (theoretically maximum) output. If the machine is capable to produce at the rate of 5 pieces / minute, and it produced 300 pieces in one hour, then the performance rate of the given machine was 100% in the particular hour.

Performance = Actual Output / Theoretical Output * 100%

Quality:

Until now the OEE minor metrics were focusing simply on quantity. But wastes are also generated on quality side. The Quality metric focuses on the quality ratio, which is the share of good products compared to the number overall produced parts. If we only produce good parts according to the specification, our Quality rate is 100%.

Quality = Good Products / Actual Output * 100%

Having all three minor metrics, the calculation of OEE is simple:

The following table summarizes the OEE mapping, containing the losses of availability, performance and quality. Focusing on the measured losses is the key to improve OEE.

The detailed structure of OEE calculation | |||||

| Availability | A | Potential production time | |||

| B | Actual production time | Losses: material shortage, machine breakdown, tooling failure, unplanned maintenance | |||

| Performance | C | Potential (theoretical) output | |||

| D | Actual output | Losses: reduced machine cycle time (under design capacity), minor stops, worn equipment, operator inefficiency, mishandling | |||

| Quality | E | Actual output | |||

| F | Good products | Losses: scrap, rework, retest, expiration of material | |||

Let’s see a complete example for OEE calculation. We will analyze the OEE of a production line in one given shift. Example: the line produces a particular product in the given shift with a given availability, performance and quality rate.

The detailed structure of OEE calculation (Example) | ||||||

| Availability | A | The potential production time in one shift is 480 minutes – 50 minutes break – 10 minutes planned maintenance = 420 minutes. A = 420 | B / A = 390 / 420 Availability = 0.928 | |||

| B | The actual production time is 420 minutes – 30 minutes loss = 390 minutes. B = 390 | 30 minutes loss due to breakdown and material shortage | ||||

| Performance | C | The potential (theoretical) output of the line is 2 pieces / minute. It means the line should produce 2 * 390 pieces = 780 pieces under 390 minutes. C = 780 | D / C = 710 / 780 Performance = 0.910 | |||

| D | The actual output of the line was 780 pieces – 70 pieces = 710 pieces during the complete shift. D = 710 | Loss of 70 potential pieces due to minor stops and reduced cycle time of one machine. | ||||

| Quality | E | The actual output of the line was 780 pieces – 70 pieces = 710 pieces during the complete shift. E = 710 | F / E = 680 / 710 Quality = 0.957 | |||

| F | The line produced 710 pieces – 30 pieces = 680 good parts. F = 680 | Loss of 30 parts that were scrapped or reworked. | ||||

| Availability = 92.8% Performance = 91% Quality = 95.7% | ||||||

| OEE = 0.928 * 0.91 * 0.957 = 0.808 OEE = 80.8% | ||||||

OEE is not only the one major metric that was mentioned before. The other one is TEEP, which stands for Total Effective Equipment Performance. TEEP relies on OEE and a forth minor metric which is loading.

OEE and TEEP | ||

| TEEP | Loading | |

| OEE | Availability | |

| Performance | ||

| Quality | ||

Loading: the metric shows the scheduled operation time compared to the total calendar time. Loading contains the loss factor of unplanned operation time and planned downtime. If loading is 100%, it theoretically means we plan to produce during the whole year with no planned downtime.

By having our OEE and Loading factor, we can calculate TEEP.

Example: our average OEE is 90% throughout the whole year. We plan to run our production only on workdays, and we also consider 2 hours of planned maintenance each day.

In this case our scheduled operation time is 22 hours * (5 / 7) * 365 days, while the total calendar time is 24 hours * 365 days. The two numbers give the loading score: 5735 hours / 8760 hours, which is equal to 65.4%.

Knowing our average OEE (90%) and our loading score (65.4%), TEEP can be calculated according to the followings:

TEEP = Loading (%) * OEE (%) = 0.654 * 0.9 = 0.588 = 58.8%

By other words, the 58.8% value of TEEP means that we could almost double our production output by improving:

- Loading (by the extension of scheduled production time, which is a management decision).

- OEE (by increasing our availability, performance and quality metrics with actions and comprehensive improvement projects).

From minor shop floor improvements to wide Six Sigma projects, all can be successful to improve OEE, by finding and eliminating the root cause of “efficiency losses”.

An OEE 100% means perfect production, however it is rarely achievable. Despite that, the focus must be always on tending towards this value. A world class production is usually over 85%.

Levels of OEE | |||

| Metrics | Poor OEE | World class OEE | Top-notch OEE |

| Availability | 80% | 90% | 95% |

| Performance | 80% | 95% | 95% |

| Quality | 95% | 99.9% | 99.9999% (Six Sigma) |

| OEE | 60.8% | 85.4% | 90.2% |

It is important to note, that the term “Good Products” mean products that conform to the specification according to the actual test coverage. Customer claimed parts are not counted in the OEE, so the good parts are those ones, which can be shipped to the customer.

OEE and TEEP calculation is easy, however it can be quite complex and difficult in case of high number of different part numbers, lines, etc. It is suggested to use special-purpose software intended for OEE tracking

Conclusion

- OEE stands for Overall Equipment Effectiveness. OEE is a universally accepted set of metrics, used by manufacturing entities.

- OEE is a productivity metric that represents the ratio between actual good output and theoretical good output. It contains three minor metrics, which are availability, performance and quality.

- The principles of OEE were deployed by Seiichi Nakajima in 1982.

- TEEP stand for Total Effective Equipment Performance.

- TEEP shows the overall utilization performance against calendar time. It is calculated by the multiplication of loading and OEE.