As a freshman, I first came across the term Principles of lean manufacturing. At seminars on the organization and management of production, we calculated production reserves, speed, and consumption rate, and made complex calculations. In addition, there was work experience at a production enterprise of the some type – in the most negative sense of the word.

Therefore, the very idea that it is possible to work almost without reserves and losses, the work not “according to plan”, but “according to needs” seemed seditious.

In addition, the teacher herself was not very well versed in production issues and her knowledge in the field of production organization was exhausted by notes taken from a couple of textbooks. But the very idea of working without reserves and losses “hooked” me and I began to look for additional materials on this topic.

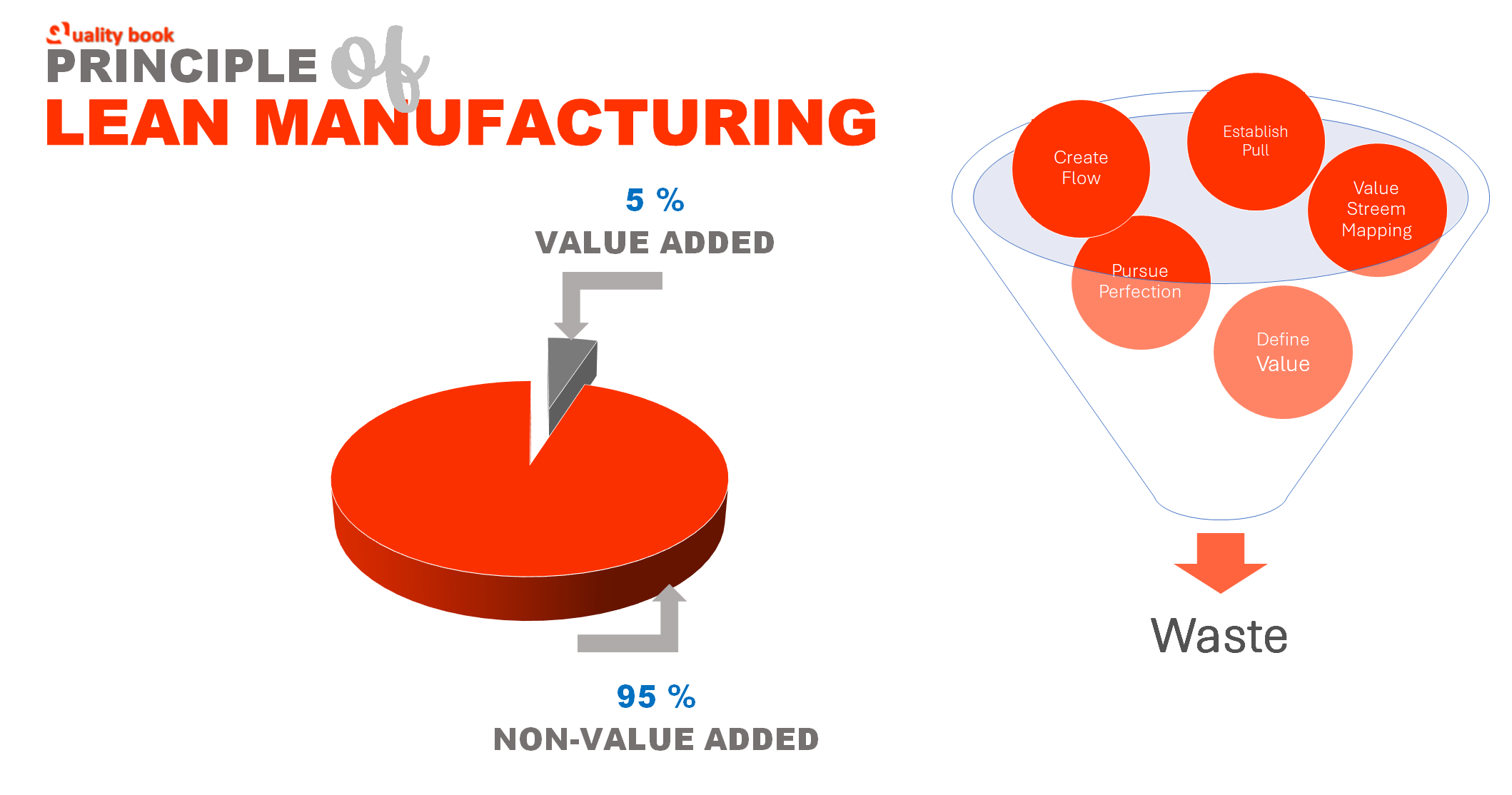

Studying materials on lean manufacturing, I realized that this is a huge and immense topic, and the principles of lean production can be applied not only in the factory at the machine, but also in the office, and even everyday life.

The most revealing in this regard is the workplace organization system 5S. Of course, we all know perfectly well that things should be store in their places and return the item to where it came from.

It is much easier to maintain order at all times than to arrange “fearless” spring cleanings once a week or a month, clearing the “Augean stables” on the desktop.

But how many do?

A well-known saying says that people are not judged by themselves. Contrary to this folk wisdom, I decide, first of all, to apply the principles of lean production on myself and judge the effectiveness based on my own experience of using them.

As a legacy from my predecessor, I receive several cabinets in which all correspondence with partners was carefully and accurately collecting, paper copies of incoming and outgoing letters register in special journals.

There were not enough cabinets, so next to the desk there was a specially designated table for documents. Which was neatly filling with folders. I also got a table with two organisers, in which there were sharpen pencils, pens, markers, scissors, paper clips and other stationery.

On the table there was also a desk clock, a business card holder, and a box with stickers. A similar pattern was on the desks of other employees. Also, in the department there was a habit of working with reference or reporting information in printed form.

Corrections to documents were made with a pencil or marker, and then the necessary corrections were made to the documents, which were again printed and checked.

To save paper, documents were printed on so-called “drafts”, i.e., on old unnecessary documents in which one side was clean. There was a lot of paper, and they were everywhere, so it was immediately obvious that the department was working hard.

Experienced

Prior to joining the new location, I have been working in a department dedicate to the control, adjustment, and coordination of cargo transportation from around the world. There was practically no “paper” work. All the necessary information about the location of goods was on a specially developed portal. If necessary, we copied the data to the desired container and sent it by e-mail to colleagues.

Carriers sent us scanned copies of shipping documents for verification, and we, in turn, confirmed the correctness of filling, or pointed out errors by phone or e-mail. So, when I came to the new department, I was just shocked by the number of papers.

Having already had some idea about lean manufacturing, I decided to use the 5S approach in order to free up my workplace and ensure that the desktop has only a laptop, a landline phone, a notebook and materials related to the direct work that I am doing right now. These can be financial documents, commercial offers, contracts, etc.

Start as HEMAN

Since I constantly carry a laptop and a notebook with me, I promised myself that at the end of the working day I should have only a phone on my desk. Work with documents should be completed and the document should either be sent further to the next department, or transferred to the executor, or removed to a special folder for further work the next day. The main thing was to fulfill the promise given to himself – to leave the workplace in perfect order and cleanliness, without indulgences and reservations.

As you know, the most difficult thing is to keep a promise made to yourself. So, you need to go through only five steps:

seiiri (sorting), seyton (maintaining order), seiso (keeping clean), seiketsu (maintaining order) and shitsuke (improving, developing a habit).

There were no problems with sorting (seiri).

I started by putting my workplace in order. Due to the specifics of the work, I constantly have to work with documents – these are official letters, contracts, commercial offers, reports of subordinates, reference materials and presentations of potential partners.

First, I sorted the papers – I scan the letters and commercial offers and saved them on the computer, and sent the paper copies to the shredder. At the same time, the cabinets were freed up – some of the documents were transfer to the archive. The other part was also scan copy and stored on the clerk’s computer, and backup copies were duplicate in a special folder on the company’s server.

Paper copies were also destroy, since due to confidentiality requirements they could not be hand-over to the waste paper collection point. Since the originals of all incoming letters are store in the office or archive. There were no problems with the destruction of copies.

Thus, immediately freed up space in the cabinets and, on one of the vacant shelves. I also remove excess stationery, leaving myself only the necessary amount for current needs.

It should be note that the efforts were not in vain. Having remove unnecessary papers. It became much more convenient to work, it is immediately clear what issues remained unresolved. Piles of papers on the table make me feel cluttered and the order on the table, figuratively speaking, makes it easier to breathe.

What achieved ?

After sorting, only a laptop, a phone and a notebook remaining on the table. Thanks to this, the problem with the observance of order was immediately solved – every “extra” piece of paper or every “extra” object immediately catches the eye, demanding to remove it in its place. Having established for myself the above rule and following it, imperceptibly for myself it was possible to solve the problems of seiso (keeping clean) and seiketsu (maintaining order).

There is an opinion that for consolidation it is necessary to repeat the action for 21 days in a row and soon it will become a habit.

I’m afraid this rule doesn’t apply to me. It’s been a lot more than three weeks since I’ve been trying to follow the 5S principles when organizing a workplace, but still, every night I have to make an effort to overcome the temptation to lump everything down and put everything in its place.

From time to time, the top management of the company made a tour of the building and at these moments employees frantically hid all the extra things and papers in bedside tables or cabinets. It happened that the employee did not have time to remove the papers and caught the eye of the management.

He had to listen to lectures and valuable instructions. After the threat had pass, all things were moved back to the tables. Having come to the new department, I was directly eager to restore order in the workplaces of my subordinates.

Example

However, having seen that the process is unlikely to be established by force, it was necessary to temper the reformist fervour and, by his own example, day after day, to prove the effectiveness and effectiveness of the principles of the 5S. It took a long time before the employees of the department also began to apply them.

I want to note that our management is conducting an active campaign to implement the 5S system at production sites. Some processes and functions are visualize to assist workers in performing operations.

As another evidence of the effectiveness of the 5S, namely the principle of (improvement, habit development), we can cite the process of installing metal frames for loading cars into a container. Previously, the slinger measures the distance from the wall of the container with a tape measure, drew a mark where the rack should stand. Sometimes the mark shifted by a couple of centimeters in one direction or another.

Effectiveness of 5S noted

As another evidence of the effectiveness of the 5S, namely the principle of sitsuke (improvement, habit development), we can cite the process of installing metal frames for loading cars into a container.

To eliminate possible inaccuracies, as well as speed up the processes, we made easily removable pipe templates in advance, allowing you to automatically align vertical racks and install them almost instantly without deviations:

I believe that 5S is a very necessary and useful system that allows you to structure and systematize not only the workspace, but also, without exaggeration, your own life.

The 5S system is just one of many lean manufacturing tools that allows you to achieve the main goals of this management concept – i.e. to eliminate losses as much as possible and strive to implement processes that have the greatest value. Continuing to talk about my attempts to implement the principles of lean manufacturing in a single unit, I cannot but talk about “muda” – losses that I face in the course of my work.

As you know, there are eight types of losses:

- losses due to overproduction;

- loss of time due to waiting;

- losses in case of unnecessary transportation;

- losses due to unnecessary processing steps;

- losses due to excess stocks;

- losses due to unnecessary movements;

- losses due to the release of defective products;

- unrealized creative potential of employees.

I think that in the vast majority of companies in the post-Soviet space you can find examples of the above losses. Our company is no exception, despite the fact that work is underway to implement the principles of lean production.

Study of logistics services

The specifics of my division are related to the search and selection of carriers, the study of the logistics services market, the conclusion of contracts with carriers and the conduct of financial settlements.

In addition, we control the timing of shipment and delivery of goods by nominated carriers. In our work we are constantly faced with losses associated with waiting, unnecessary processing steps, unnecessary movements (in this case, aimless movements of documents between departments).

Our production is one of the largest in the region, the company’s factories are located in three cities, and the number of employees exceeds 9,000 people. Therefore, there are always situations when it is necessary to urgently deliver goods.

Since we work with more than 300 suppliers from 30 countries and 4 continents, the issue of timely delivery is very acute. No less acute is the issue of the cost of transportation. Every day we have to decide whether to deliver urgently or to deliver cheaply. The task, in principle, is solvable.

Tasks and Principle

However, it is necessary to work out the issue of delivery with logistics companies in a short time and choose the most acceptable offer. Now the process looks like this – the suppliers are determined with the goods, they transfer the order for delivery to us. We prepare a request to transport companies with all the necessary details, send them to several dozen carriers, then analyze their rates and, if necessary, send a second request. After analyzing the rates, we select the most suitable offer and conclude a contract.

After the conclusion of the contract, we coordinate the shipment work between the carrier and the sender. We are still engaged in mailing manually – i.e. there is a database of companies that we once selected as potential carriers. This method has a number of obvious advantages and disadvantages.

The advantages:

The rates for a particular transportation, as a rule, are 10-20% lower than the rates for six months or a year. Another advantage is the large number of carriers, which practically eliminates the possibility of price collusion, stimulates competition and allows you to get the maximum quality at the lowest price. Of the shortcomings: a rather long and time-consuming process of selecting a carrier – it is necessary to re-conduct bidding every time and contract the carrier, passing each time the process of internal coordination.

Very often, suppliers provide the necessary information about the contract being concludes too late or this information is incomplete. In addition, there are risks of late delivery of transport for urgent transportation. Also, the disadvantage is the “human factor” – the responsible employee may not send a request to one or another carrier, or not notice his answer among many others.

Such a process has the following main obvious losses (although, if you dig deeper, you can find examples for other types of losses):

- Losses due to overproduction – it happens that during the “rush” there are many requests, commercial offers and similar information that need to be urgently processing. Sort and sent to transport companies;

- Loss of time due to waiting – sometimes it is the other way around – the customer until the last moment can not decide from which supplier the cargo will be deliver and logistical are force to wait for the “go-ahead”;

- Unrealised creativity of employees – most of his working time the employee is force to process the information receive and he does not have free time for self-employment

- To implement their ideas, to improve the working process.

In general, the process is require to establish and, despite all its shortcomings, still works. However, in the XXI century, with all the level of technology development, it is shameful to use the methods and approaches of the last century. In this regard, we have developed with colleagues the idea of a single tender portal and now, together with colleagues from the IT department. We are engage in its creation.

System

The idea of such a portal is not new and is use by most large companies. When registering, the potential carrier will fill out special forms, indicating all the required information. The system will verify the accuracy of the specified data available in open sources (for example, TIN, legal address, etc.).

Also, the system will automatically sort companies depending on the type of services they provide (rail, road or air transportation, consolidation services, etc.). Depending on the algorithm introduced, the system will sort logistics companies by rating. In the future, the operator will be able to make additions to the rating – include in the top list, or display in the “black list”.

Thanks to the system, it will be possible to increase the transparency of the selection of carriers and speed up the process of notifying them and analyzing their proposals. Also, the system will be able to notify all interested participants about the opened tender or planned transportation. The system will allow you to automatically collect and sort large amounts of information, freeing employees from routine work.

Tasks

There are many advantages, but there are also disadvantages – it is necessary to correctly prescribe the selection algorithm and pay great attention to the security of the portal. However, in general, there are still more pluses than minuses and the portal will soon be create. But all the above efforts will be useless if the company’s employees do not act coherently as a single organism.

It seems logical for each unit to perform its functions well. But it should be understanding that production is not a closed system and any unit is both a consumer of the results of the work of one unit and a supplier of work for another division. Therefore, it is not enough to perform only your functions, you need to think about how the result of your activities affects another department and whether you create problems for them.

Figuratively speaking, our customers are Supply Chain and Purchasing. And how well we perform our work – i.e. deliver the cargo to the plant, depends on the production schedule and the overall implementation of the plan.

On the one hand, automobile production must be massive in order to recoup its costs and make a profit. On the other hand, it must be flexible to respond instantly to market changes. This requires maximum voltage from all units. Including logistics. Therefore, it is extremely important to deliver goods on time, smoothing and filtering possible errors of other units. If the Purchasers later entered into a contract, this does not mean that the cargo can arrive later. This means that Logistics has less time to deliver it.

Conclusive

Therefore, it is very important to be constantly in touch with all involved units and work in parallel where possible.

About three years ago, we often had disagreements about who should work and how – Procurement said: “Here’s an application, here’s a deadline, how you want to bring it.” On the other hand, logisticians objected: “The application came too late, we do not have time to meet the deadline.” Blaming each other and proving our case is a dead end in this case.

We need to negotiate in a good way. Therefore, we arranged and a kind of internships for employees in Procurement, Logistics and Supply Chain. The employee, firstly, established personal contacts with colleagues, and secondly, began to understand how his actions or inaction affects the work of other departments. In addition, many processes were introduce and standardize. Which made it possible to reduce the vast majority of conflict situations. Of course, from time to time, there are “overlaps”, but they are of a single nature and are instantly eliminate.