Quality Assurance Matrix (QAM) is a systematic process and analysis tool, with the aim of eliminating potential risks and previous quality concerns on the base principles of Plan-Do-Check-Act (PDCA).

QAM helps us to identify process phases we need to focus on, in order to eliminate defects. QAM contains the whole manufacturing process chain, together with relevant information about both potential and occurred failures, and how these failures are prevented, or detected by quality gates.

Benefits

QAM is an important tool not only to cover existing failures, but also to predict them. Like Failure Mode and Effect Analysis (FMEA), QAM is essential in planning, with the benefits and features, such as:

- Gives a structured and systematic overview of the production process and process risks.

- Useful in New Product Introduction (NPI).

- Useful in case of already existing production.

- Helps to identify potential failures (prediction).

- Helps to effectively eliminate existing risks / occurred failures.

- Very useful complement of FMEA and CP.

- QAM is Living document.

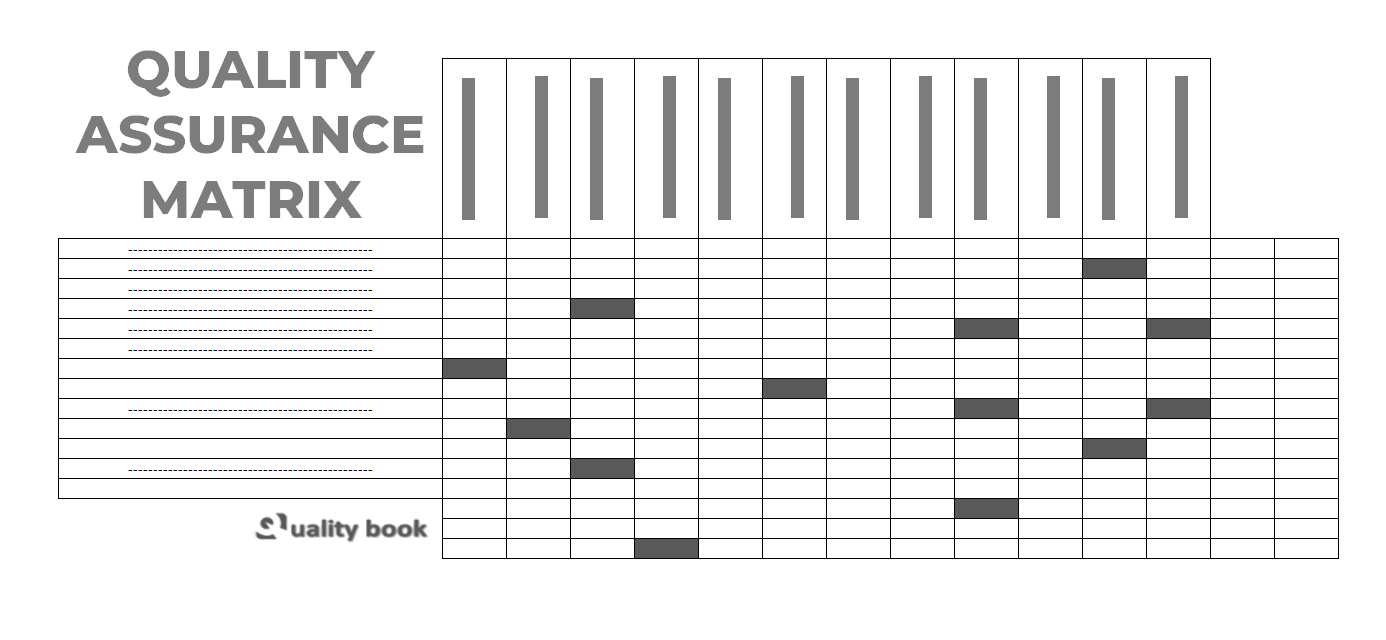

There is no standard, that regulates the format of QAM, and every company or organization sets its own QAM differently, but the basics are usually the same. The following example is used in the automotive industry:

The QAM consists of the following major sections:

- Line data: covers the manufacturing stations and process steps (including testing).

- Information of failure / claim: contains all major information about the external / internal failure.

- Number of occurrences (before measures): contains statistical data about the occurrence of failures (claims from end customers, internal notifications by staff, etc.) before the implementation of new measures.

- Stations with failure detection: contains the list of manufacturing stations, including test stations in the order of process flow.

- Counter-measures: enlists all measures, with implementation data, the verification of effectiveness, and whether the information has been transferred to other lines / departments / plants in the frame of Lessons Learned.

- Number of occurrences (after measures): contains statistical data about the occurrence of failures (claims from end customers, internal notifications by staff, etc.) after the implementation of new measures.

- Updated documents: contains information whether any linked documents were updated, such as FMEA, CP, 8D report.

Integration QAM

For new products, use QAM together with FMEA during the Advanced Product Quality Planning (APQP). It helps you to overview your predictive quality level, and helps to define preventive measures and quality gates. The use of QAM should also be in conjunction with the creation of Control Plan (CP).

Integrate QAM into your Continuous Improvement (CI) process, and update your QAM regularly with:

- Potential failures (identified during FMEA workshops).

- Potential failure reported by line staff.

- Internal failures that occurred.

- External failures (complaints from customer).

- Failures, that happened on other lines, but mean risk also in your relevant production (lessons learned).

When a measure is taken, and conducted in the QAM, also update your FMEA, CP, 8D report.

Conclusion

- QAM stands for Quality Assurance Matrix.

- QAM is a systematic process and analysis tool, with the aim of eliminating potential risks and previous quality concerns on the base principles of Plan-Do-Check-Act (PDCA).

- It contains the whole manufacturing process chain, together with relevant information about both potential and occurred failures, and how these failures are prevented, or detected by quality gates.

- QAM should be used both during the planning and the serial life of the product, in conjunction with FMEA and CP.