What is TPM?

” Total productive maintenance (TPM) is integration of the system for zero defect products with zero wasted activities by implementing effective maintenance by everyone’s involvement.”

The purpose of the total productive maintenance (TPM) is addressing main issues such related to people, equipment, methods, losses and waste and performance measurement. In total quality management (TQM), Total Productive Maintenance (TPM) is excellent key tool is improving the existing manufacturing facility and equipment at its highest productivity level by effectively implementation of all location of organization.

It is help to build effective bridge to cross is to finish barriers between production and maintenance personal that hence they people can works together. This is one of most important plant improvement methodology which helps continuous improvement of the existing processes through effectively organizing employee involvement and empowerment.

Involvement of employee closely relates with target areas is a necessary for the successfully implementation process in the total productive maintenance (TPM). With the purpose of increase individual capability, decision making and ability to keep defect free product with zero waste. As results is personnel pride and job satisfaction as well as financial benefits for the organization.

Why Total Productive Maintenance (TPM) – Benefits of TPM implementation

- It is focus on key performance indicators or objectives such as equipment break downs and idling, quality defects, productivity, labor costs, inventory shrinking, zero accidents, and promoting employees.

- Through total productive maintenance you can maximize overall equipment efficiency.

- Biggest benefit of Total productive maintenance is a complete system of maintenance for machine and equipment for life cycle.

- Creating best working environment, promoting the participation for all employees.

- Minimize or eliminate possibility of waste generation from machines by effectively change, modification or alteration economic environment.

- Increasing significant production timing without reducing product quality.

- Reducing or eliminate possibility to defective products due to mechanical errors.

- You can reduce expenses related to maintenance approximately 25% to 30% of total manufacturing costs.

- You can build a system to prevent some type of losses such as zero defects, zero failures and zero defects products.

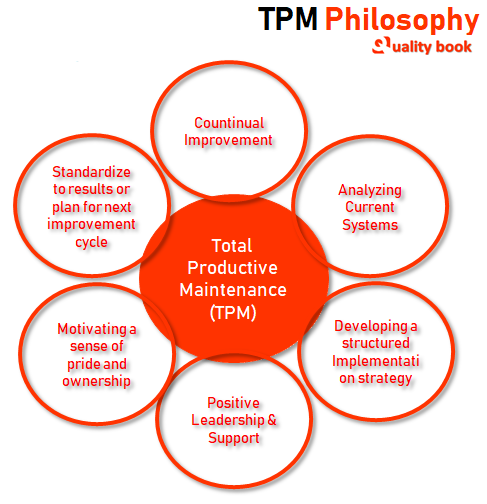

Total Productive maintenance (TPM) is broad thought

Every system having its own goals and targets but the ways can be different and the same here applicable with typical maintenance and total productive maintenance. Total productive maintenance is advanced system that helps to improve machine efficiency and also quality of product which is based company objective. Some general total productive maintenance (TPM) objectives and what organization mostly define targets for its internal maintenance system improvement:

- A. OEE (overall equipment efficiency) – Zero break downs, zero failures, zero accident, and zero defects)

- B. To improve machine & equipment reliability, and maintainability as contributors to quality and raise productivity.

- C. To enhancement in existing maintenance plan and improvement in maintenance system.

- D. To educate operators about equipment related expertise and skills.

- E. Cycle time reduction: by implementation of TPM, you can minimize cycle time shorter by reduction in equipment breakdowns, minor stoppages and idling equipment.

- F. Setup Reductions: Well-planned machine setup can reduce time and cost significantly for frequent production lines.

- G. Cost reduction: to establish analyze and improvement of machine setup time, unexpected breakdowns, preventive maintenance for cost reduction.

- H. Capacity Expansion: You can increase your production capability if you well planned, controlled processes with effective maintenance plan, by reducing maintenance and cycle time.

- I. Maintain accident free working environment.

TPM System

TPM System: Table

Purposes:

|

| Unique Feature The unique feature of the total productive maintenance (TPM) is making a people positive about equipment care individually, remember that the operator is the best condition monitor. TPM improves spirit in everyone that everyone is responsible for every equipment installed in manufacturing facility. |

Objectives

|

Benefits

|

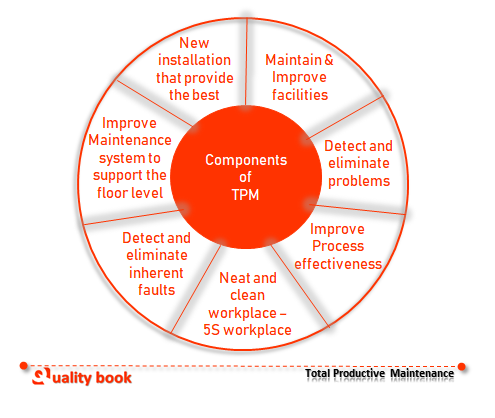

Components of TPM (Total Productive maintenance)

Maintain & Improve facilities:

The purpose of this component of total productive maintenance is to maintain, and continuous improvement of the existing manufacturing facility by responsible personnel, such as maintenance team must carry out all the major repairs, improvement in weak points and eliminate deterioration, planning of each equipment for maintenance, carry out periodic and preventive maintenance, and collect the information from the plant to analyze breakdowns and performance. The operation personnel are responsible for maintain equipment with initial require condition and prevent deterioration, monitor machinery effectiveness, regular checking and verification and improvements.

Detect and eliminate problems:

This component helps to detection and elimination of faults and problems, which are cause breakdowns and stoppages, slow down the processes, changeovers difficult, and make the process life cycle difficult.

Improve Process effectiveness:

TPM allows establishment, monitoring and improvement of process effectiveness by controlling on some big losses to recognize, measure and reduce. The big losses such as breakdown losses due to machine failures, machine starting, change over setup and adjustment losses, idling machinery, minor stoppages and speed losses, scrap and re-work losses.

Neat and clean workplace – 5S workplace:

This total productive maintenance (TPM) component describes good housekeeping in the workplace i.e. it is supporting 5S methodology implementation in organization. As we detailed in previous article, how to implement and work 5S methodology in organization. [ Read full article: 5S Methodology ]

Detect and eliminate inherent faults:

This TPM component describe identification inherent faults which can instinctively in machinery, design or in regular method of manufacturing processes. This system assists to reduce their effect wherever possible. inherent faults can be identifying through establish team to focus on faults which inherent in various processes and to improve overall effectiveness such as reduction in setup time, seamless production and maintainability improvement.

Improve Maintenance system to support the floor level:

This TPM component describe how the TPM provide advanced maintenance systems to support floor levels / manufacturing facilities through presenting advanced techniques and tools to restore accurate condition of machinery. The team prepare plans and implement maintenance system with available resources, and multiple skills from team provide proper solution for complex issues with mechanisms.

New installation that provide the best return:

This TPM component describe, TPM help in selection & installation of machinery by explicit approach, professional and structured system and as an integral part of the overall manufacturing system.

8 Pillars of TPM (Total Productive Maintenance)

The goal of 8 pillars of Total productive maintenance is to reduce significant losses with the ultimate aim of elimination of all losses. In this whole process, top management involvement is required because of possibility of some game changer decisions. The 8 pillar approach is a providing such a way of organizing change and a rigorous methodology to ensure sustain outcomes for the next operations.

Autonomous Maintenance:

Autonomous maintenance is structured approach to enhance personnel skill level of employee, and improve their equipment and manufacturing processes. In this section implementation, you have to train the equipment operators to minimize the gap between them and the maintenance peoples, to making an easier for both the to work as one team. Operators are best condition monitor of equipment; train & equip the operators so that the operator can identify any failure conditions, measure deterioration and fix on before it affects the process or major failure on initial stage.

Focused Improvement:

In this pillar, you have to establish small groups of employees i.e. cross functional team from different functions, for working together proactively to incremental improvement in equipment operation. This is a team based approach to drive elimination of specifically identified losses in any process. The pillar describes and work on based on PDCA (Plan, Do, Check, Act) Cycle, which can be implemented for improvement activities of any complexity in any organization.

Planned Maintenance:

The purpose of planned maintenance is improving efficiency of maintenance activities to prevent all major losses, and extends the equipment reliability in organization. The purposes of this pillar can be achieved through some activities such as daily maintenance, time based maintenance, failure analysis, prevention of recurrences, and controlled maintenance system.

Quality Maintenance:

The purpose of this pillar is to achieve zero defects in products and processes by assist and maintain equipment conditions. Mostly, quality assurance team, production team and management personnel are performing and actively involvement require in this task for implement. Team verify quality characteristics standards, investigate the conditions, raw materials, equipment and method, investigation and analysis and improving the conditions of malfunctions.

Early Management / Development Management:

The purpose of development management TPM pillar, is to reduction in product development, design, and assembling time, and improvement in quick startup stability of equipment. And that can be achieve through setting development and design goals, ease of production and quality assurance implement, and identification problems in design, first trial run & initial stage.

Training and Education:

The purpose of this 8 pillar of TPM, for establishment of technical education for equipment operators and maintenance personal. To achieve this motive needs some activities training to personnel, such as basic process of maintenance, maintenance of regular use tools and parts, prevention of leaks etc. Basic knowledge for maintenance of control equipment.

Safety, Health and Environment:

In this pillar of TOM, assuring safety and preventing adverse environment impacts are important priorities. The process must involve the requirements of safety, health and environment during any kind of maintenance planning, and implementation.

Office TPM:

The goal of this pillar is achieving zero function losses, creation of efficient offices, and implementation of fully assistance functions for production lines. this task is conducted by administration personnel and selected leaders through performing tasks such as initial cleanup, inventory management, countermeasure of problem, standardization and autonomous management activities.

How to implement Total Productive Maintenance (TPM)

As the part of the Total productive maintenance implementation program; the top management introduce total productive maintenance, introduce education and training of the TPM, basic structural formation to promote total productive maintenance in organization. Management also responsible for establish cross functional team, and discuss with the team to determine targets and goals for TPM process.

Team prepare documentation of master planning for implementation which include department wise, area wise implementation includes initiate 8 pillars across the manufacturing facility. The team also define the role and responsibility for all related personnel, but mostly equipment operators and maintenance personnel are in center of the planning, see both important personnel role and responsibility:

Define Role & responsibility for TPM implementation

To define role & responsibility in the organization, two important different departmental personnel which are pivot in the total productive maintenance activities, operators and maintenance personnel’s example role & responsibility given as below:

Operator TPM Role

- Every operators’ role & responsibility must be defined & allocated as per training provided and capabilities measured.

- Perform initial maintenance of equipment and machine such as cleaning & replacement of any parts, lubrication, checking and inspect basic parts, and safety functions.

- The organization have to develop basic skill level of each operation in monitoring & maintaining critical process parameters, easily changeover & setup, identify and fix minor issues & adjustments, and allocate the same.

- Each operator must know how to collect data, tracking equipment and performance, documentation and filling. in case any operator found weak do this, you have to provide training for it. because TPM cannot be implemented correctly without proper data collection and its analysis.

Maintenance TPM Role

- It is preliminary duty of maintenance personnel to support technical assist to each operator for maintenance activities.

- Before tasks allocation, it is important that all the maintenance personnel must verified technical maintenance skill of all existing machinery and equipment over the plant, in case gap identified that should be completed by systematic training.

- Maintenance personnel must have to proactively identify design errors and improve equipment on initial stage for error free function.

- Restore deteriorated equipment through Improvement-Related Maintenance.

- In the TPM process, every maintenance plan or periodic maintenance system should must upon analyzed data from manufacturing facility. And this task must be performed by operators for collection data, and maintenance personnel for analyze data to prepare healthy TPM plan.

12 Steps of TPM implementation

Step -1: »

The management of organization is responsible for provide environment that will help to establish total productive maintenance and implementation. Generally, management meeting is best platform for declaration and discussion with core team for planning and further implementation.

Step -2: »

Second step of the implementation program. It is education to everyone in the organization about total productive maintenance activities, individual and organizational benefits. The importance of involvement in TPM from everyone.

Step -3: »

Prepare structure to promote and sustain total productive maintenance system and relates activities once they establish. Further team must be cross functional team. That all the members are come from different functions and different levels of management system.

Step -4: »

Now the time is to define the basic total productive maintenance principles, targets and goals, benchmarks & prediction of effects. You have to define the TPM policies & quantifiable targets and analyze the existing conditions.

Step -5: »

In this phase of the TPM implementation. You have to prepare and deploy master plan. Wherein merge all associate activities of organization. Hence training, equipment and improvement maintenance management system as well as new technology must be cover.

Step -6: »

Now, we are reach at on stage where all planning is done, and time for effectively implement total productive maintenance in organization, you can involve third parties as well interested parties such as customers, suppliers, affiliated companies etc.

Step -7: »

You have to establish system for improvement the efficiency of the manufacturing herein this step of the TPM, and you have done search proper method and techniques to build a team, for its activities, diagnosis, periodic maintenance, corrective maintenance, predictive system and preventive maintenance. The purpose of this stage is to improve effectiveness of each equipment installed in manufacturing facility.

Step -8: »

For the new equipment development of easy to manufacture product and easy to use equipment for regular task, you have to establish advanced maintenance system or modify existing system accordingly.

Step -9: »

At one stage of ninth of TPM implementation, establish quality maintenance system for eliminate defects which are occur due to equipment, and the effectively implement and managing prevention of each equipment.

Step -10: »

For improvement of the efficiency of administrative and supervisory sections need to establish system. Production support, improvement of the efficiency of related sectors, and improvement of efficiency of equipment.

Step -11: »

To achieve zero accident & zero pollution cases, you have to establish and maintain safety, health and environment system, Further, you have also take care of safety requirements of each equipment, and have to prepared safe design of equipment to eliminate possibility of any incident.

Step -12: »

Complete implementation of total productive maintenance at all level of management, and define the plan for continuous improvement, reviews of system.

OEE (Overall Equipment Effectiveness)

An OEE (overall equipment effectiveness) is TPM key measure indicator, which is measure effectiveness of machinery and equipment. OEE is metrical that identify in percentage of equipment performance. And it is pre-design for identify percentage of planning of production time, and cycle time in production for particular product.

OEE = Availability x Performance x Quality

Conclusion:

Total Productive maintenance (TPM) aims at zero break down. Zero accidents and zero defect in product through use method for continuous improvement. Initially, maintenance personnel and operators establish team and work together for implementation of part of TPM. To avoiding unexpected breakdowns of equipment. Preventive conduct processes to achieve goal.