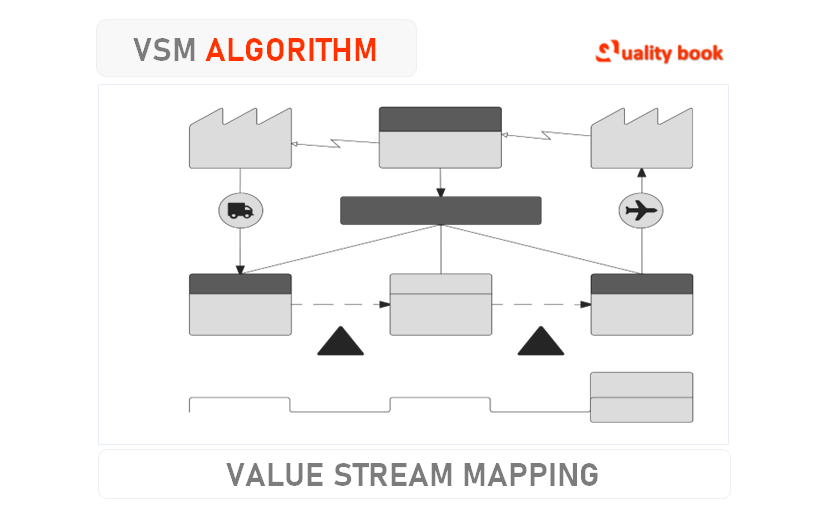

The Value Stream Mapping (VSM) Algorithm is a systematic and effective approach. It is useful for identifying, analyzing, improving, and optimizing the flow of production.

Value stream mapping is the most common method of identifying losses in the production flow of a particular product. It is mandatory when building a flow, aimed at minimizing losses and improving the synchronicity of work.

Currently, there is enough information containing the technical aspects of the use of the tool (card design, sequence of analysis, etc.).

For example, the classic editions of Router and Shook. Therefore, here I would like to draw your attention to the general algorithm for mapping the value stream, which is described in detail in the book “Value? Value. Modern mapping techniques using the 80/20 rule.

Setting up goal

The work of value stream mapping, like any other, begins with setting goals, that is, what we are going to do it for. At this stage, the goal is required to properly formulate, measure, and visualize. The leader and the working group must understand what they are working for and what they should strive for.

Preparation stage

After the formulation of goals, the preparation stage begins. Performing work to achieve goals requires the expenditure of resources and the involvement of specialists for a certain time, and this should be provided for at this stage. There are many examples in my practice when work was stopped after or during the analysis stage only because resources were not planned and agreed in advance for their implementation.

Product family

The stage of product selection, according to which the team will be forming, involves determining the boundaries of the process under consideration and, depending on the goals set, prioritizing among many different types of products. In contrast to the classical view of the choice of a family of products, there are many analytical ways of choosing based on the goals set.

Flow up

The formation of the current state of the team (“as is”) is a longer stage of mapping. Here, all stages of the process from entry to exit are discussed in detail, the necessary parameters of each stage are determined and recorded. Cross-functional team members must go through the entire flow and see for themselves the gradual transformation of the product.

The formation of the current state involves not only the visual representation of the flow and data collection, but the personal involvement of the participants.

It is necessary to imagine yourself in the place of the product and go along with it along the value stream, this is the only way to determine the value and losses in the process as accurately as possible. The related logistics and management system are considered and studied in detail.

Analysis stage : Value Stream Mapping Algorithm

The analysis stage involves processing the collected information to determine the impact sites that most affect the entire process under consideration. The main areas of analysis are the analysis of the loading of process stages (operations) under the time of takt.

The analysis of flow problems in terms of the degree of influence and potential, the analysis of the quality of manufactured products, and logistics analysis.

At this stage, some data may need to be collect or refine. Individual stages of the process (operation) may require a more in-depth analysis using other lean tools, so all further work depends on the quality of the work of this stage.

Future state stage

The stage of formation of the future state of the CFT (“as it will be”) involves comparing the flow capabilities identified in the analysis process with the necessary requirements for the maximum process efficiency.

It is more convenient to divide the future state in the process of work into an ideal and a target state. The ideal state involves a flight of fancy of the working group, as a result of which the best state that can only be imagined at a given time is simulated.

Such a state of the process is model with ideal parameters of each stage, logistics routes, information flows, etc. The target state, in turn, involves a small descent from heaven to earth and the implementation of a new state of flow based on the goals and available resources.

At the same stage, a preliminary economic assessment is carried out: a one-time and permanent benefit (in USD) from the transformation of the flow into the target state is determined.

Development Plan for Value Stream Mapping Algorithm

The development of a plan for the transition to the target state is a stage of step-by-step planning of the sequence and timing of real actions necessary for the transition to a new state of flow without prejudice to the external Customer. It is suppose to change material and information flows, physical transformations, calculations (quantity of stocks, cycle time, etc.), preparation for possible production stoppages. As well as changes in existing regulatory documentation to avoid duplication or contradictions. Depending on the specifics of the process under consideration, the set of actions included in the plan may vary significantly.

Implementation stage

Further stages, for example, the stage of implementation and stabilization, are no longer directly related to the use of the CFT tool, since the purpose of mapping as a tool is to identify losses and determine the most effective possible option for building a flow.

The main thing to remember is that the work must be complete, the implementation plan must be a binding document. There are no perfect results at the same time. Any system that has been interfere with takes some time (depending on the quality of the system and the degree of intervention) to start working stably.

During the implementation of measures, close monitoring of compliance with changes should be ensure. New standards should be testing in practice, staff should be train, inform, and gradually get use to the changes.

Summary Table

To imagine the consequences of skipping a step, let’s turn to the table:

| № | Stage name | Consequences of skipping a stage |

| 1 | Goal setting | Decrease in efficiency due to wasted resources, reducing the level of motivation of the working group. |

| 2 | Preparation | Decrease in efficiency due to the lack of rhythm of work, inhibition of the process |

| 3 | Selecting a product (product family) | Reduced efficiency due to exposure to small parts of the flow |

| 4 | Formation of the CFT “as is” | Disruption of work |

| 5 | Analysis of the CFT | Disruption of work |

| 6 | Formation of the CFT “as it will be” | Disruption of work |

| 7 | Develop a transition plan | Disruption of work |

| 8 | Further steps (implementation) | Disruption of work |

Algorithm summary

Despite the fact that not all stages of the mapping algorithm conduct disruption of work (non-receipt or zeroing of results and meaninglessness of continuing work), each of them affects efficiency as a whole.

The loss of efficiency of work at each stage by 10%, no matter how it is measure, from a purely mathematical point of view, gives only 100.47% efficiency at the eighth stage (implementation of measures) instead of 83%.

You can calculate the compound interest yourself 0.97 * 100% = 47.83%. It should be remember that each stage contains a few more small steps, containing temptations to ignore them and potential opportunities for making mistakes.

Thus, by performing all the required steps as accurately as possible, we increase the potential efficiency of the functioning of the target state of the process, and, therefore, strive for the most effective final result.

Conclusion

Yes, the most important thing is not to take mapping as a formal procedure. Actually, it’s not about the map, it’s not about the exact seconds and meters of measurements. The most important thing is to go and see, breathe the air, chat.

I met here an interesting expression “look at your fish” with these words the professor laid out. The fish on a platter in front of the students and forced them to look at it :).

The essence in the end boiling down to the fact that behind the usual. In this case, the fish, like a fish, see the little things and details from which it is possible to build logical structures describing the essence of the observe object or process.

So it is with the map: Yes, every day we walk past the process, and sometimes we dive headlong into it. But mapping forces us to take a step aside and “look at our fish”:)