In today’s digital world, the management concept of modern quality management has become very broad. It is a “house of quality” that has developed a noble tool and expanded it to include various tools and methods of analysis, management and control.

“The House of Quality (HOQ) is methodic tool for structuring functions for product quality, in which makes easier to establish management, analysis as well controls over actions for customer requirements.”

In fact, the “house of quality” structures the wants and needs of customers as a method of creating quality functions. So that the quality of the product can be ensured. Any business requires proper management of functions and processes to ensure quality to its customers. Which covers every stage of the product life cycle including the creation of the final product.

What can be gained from this method?

In this method work is carried out from pre-investment study to pre-sale preparation, which can realistically specify the complete requirements of the customer.

- Covers the identification and determination of indicators that are most important to consumers.

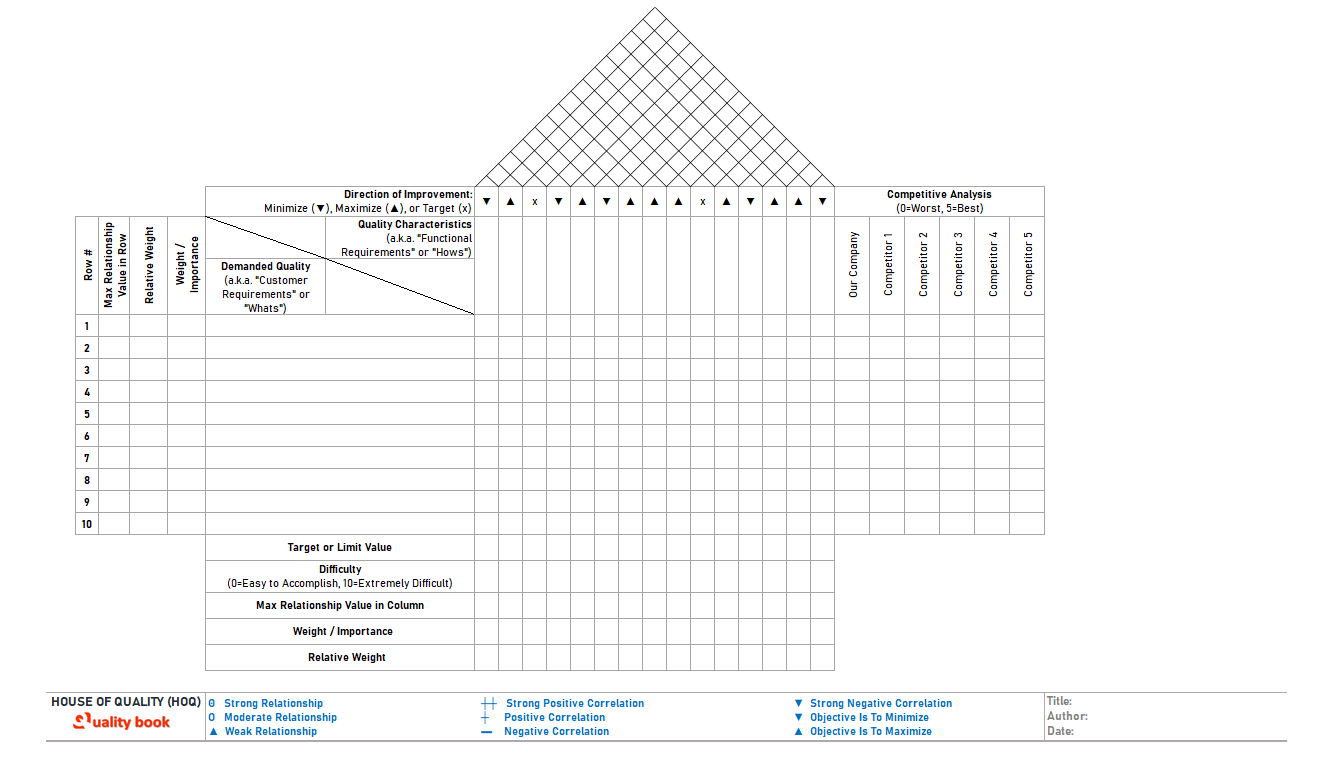

- A house of quality is essentially a table or matrix. It explains the relationship between real quality indicators, which are consumer properties, and auxiliary indicators, which are technical requirements.

- It makes it easy to translate all customer requirements into specific technical specifications.

- Identification of valid components that need to be modified and added to meet all requirements;

- Clarifying the order of change of goods in relation to customer’s price and quality desires.

House of Quality is a basic scheme for ensuring the interconnection of cross-functional design tools. This allows people who are involved in solving different problems and are endowed with different responsibilities to discuss the order of design work with knowledge using the grid structure of “quality houses” as evidence.

The concept of House of Quality

As you know, this is a graphical method that determines the relationship between customer needs and corresponding product performance. Starting with an analysis of customer needs written in the rows of this home construction matrix, the weight characteristics of the product are shown.

The matrix center and edge are the relationships of this set of information that guide new design decisions. As a result, customer needs are translated into technical specifications for products or services, allowing design to maximize customer satisfaction.

House of Quality is suitable for application:

- When it comes to analyzing customer needs;

- while translating the customer’s needs into a language the organization can understand;

- There are trade-offs when needs conflict;

- When you start designing a new product or service.

How to create House of Quality? Let’s understand step-by-step.

Left Wall Content [“What are the customer’s needs?”]

- Here on the left side of the house, all the needs of the customer are displayed, especially the feedback receiving by the customers, the product and all its information in the customer’s own language.

- Using rankings to indicate which of the information received from the customer is most important. For example, if we use 1 to 5, consider 5 as the most important. In this way, align the requirements according to the index number.

- Sub and full weight. See “Precautions” for details. Top-Floor Content: Product or Service Features – “How-To”

- Write the features of the product or service on the top floor as a list. Choose measurable features. that directly affect customer needs and are express in the technical language of your organization.

- Add another line at the top floor with symbols to indicate if characteristics need to be improved or reduced to better meet customer needs. Commonly used symbols are + and – or ↑ and ↓.

- Add additional information about customer needs: customer complaints, selling points, competitive targets, improvement factors. Add more information about the product or service: price, cost of handling complaints and technical difficulty.

Room Content [Matrix of Correlations]

Here in this part, the relationship between product characteristics and customer requirements is shown. Symbols are use to indicate what is positive or negative, strong or weak. A Hawes matrix of product or service attributes-correlations can be use in rooftop content. Symbols can be used to represent the interrelationships between product or service features, meaning numerically, or “how many”.

Basement Materials [Goal Matrix]

A basement is a unit of measurement representing the characteristics of a product or service along a row. Basement also records data about the performance of the company’s or competitors’ existing, comparable products or services. Or consumer demand assessments are shown similarly, using a relative scale of 1 to 5 and different symbols to represent different companies.

On the right wall [Analyze and set targets]

Any product that is going to be included in the “House of Quality” has to be weighted for the characteristics of that product. In the center of the group house is a numerical scale symbolizing the relationship, usually using 1 / 3 / 5 or 1 / 3 / 9 to mean weak, strong and very strong respectively. Starting with the first column, each relationship value is multiplied by the customer demand importance (or absolute weight, if used), and the result of the entire column is added, and the weight of that column of characteristics is added. In immediate rows, product or service attributes are ranked, with the attribute with the highest weight score coming first, and so on.

Determine target values for each product or service characteristic. Gather all of the Quality House information to set appropriate goals for the new design. Record the target value in a row in the basement.

Conclusion

As we know that Quality Function Deployment (QFD) is consider to be the most effective technique in the field of quality planning. This framework creates the ability to structure customer needs and wants through the deployment of supporting activities functions and operations at each stage of the product’s life cycle.

To explain the needs of customers, it is necessary to carry out QFD, in which the main types of customers can be determine. Quality tools have to be used to collect and analyze the information received through the voice of customers, to structure the requirements and structure. Especially in the manufacturing sector, the requirements receiving from the voice of the customers have to be converted into the engineering characteristics of the product as well as the economic requirements.