Before an experiment can be conducted, the experimental design must be carefully planned to ensure that experimental objectives can be accomplished, assumptions required for hypotheses testing and data analysis are valid, randomization requirements are met, and the experiment is reproducible.

The experimental design refers to the specific manner in which the experiment will be set up and conduct and the plans for data collection and analysis. Specifically, experimental design has to do with the precise way different treatments (control factors) are administer to experimental units (subjects, parts, etc.) and what information is to be collect on the experimental units and other conditions that might affect the experimental units.

What to include in Experimental design?

An experimental design should contain the following:

- Clear statement of the experimental goal or problem to be address by the experiment.

- Determination of the response variable(s), or outcomes, to be study.

- Specification of the control factors to be includes and vary in the experiment to determine their effects on the response variable(s)

- Specification of the control factor levels (or settings) to be tests in the experiment.

- Identification of uncontrollable factors or variables that might affect the response variable(s) and that will be record or measure for each experimental unit.

- Identification of controllable factors not to be include in the experiment and the level or constant they are to be held fix at for the experiment.

- Statement of how to conduct the experiment, to include:

- Test sequence, including required randomization.

- Changing factor level settings

- Plans for data collection.

- Description of data analysis plans, to include:

- Specific analyses and hypotheses tests that address the experimental objective.

- Assumptions of analytical techniques (e.g., independence and normality) and how satisfied

Designs

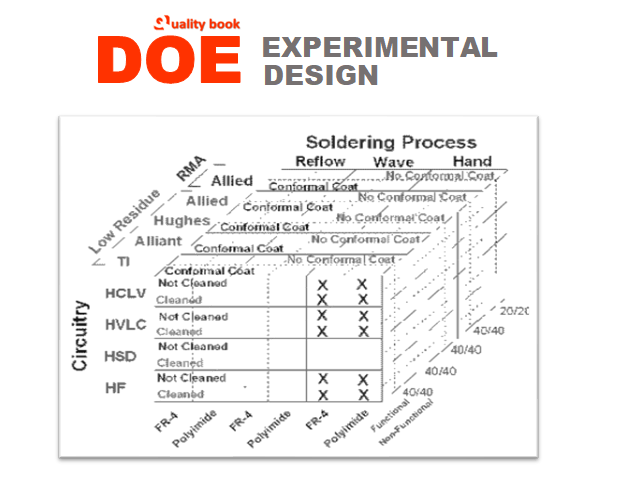

Soldering machine using new soldering process that was evaluated and qualified by a comprehensive test program that incorporated a series of experimental designs.

Several classes of experimental designs exist. Fully crossed factorial designs include every control factor level crossed with every other factor level in the experiment. Full factorial designs, with repetitions, allow hypothesis testing of every factor effect and all possible factor interaction effects on the response variable.

Some designs attempt to maximize information from an experiment with as few experimental units as possible, which can be important when the units are expensive, or the experiment is time-consuming per unit.

These designs include 2- and 3-level fractional factorial designs, Plackett-Burman designs, and response surface designs, such as Box-Behnken and Central Composite. In addition, there are designs that can handle restrictions on randomization, such as nested and split-plot designs.

Benefits:

- Assists in clarifying experimental objectives.

- Ensures results from the experiment address the overall experimental goals.

- Maximizes information from the experiment.

- Can provide most efficient use of testing resources (experimental units, time, etc.) while maximizing information.

- Forces thought given to what is being measured and data analysis techniques, which oftentimes influence the way the experiment needs to be conducted (e.g., to satisfy analytical technique assumptions)

- Maximizes chances of the experiment being successful.

Experimental design for low-residue soldering task force project to evaluate and qualify low-residue soldering for military and commercial applications.

Capabilities:

- Formulating experimental designs for experiments in a wide variety of manufacturing applications

- Determining goals, response variables, factors, factor levels, appropriate hypothesis tests, and analysis methods for the experiment.

- Data analysis, formulating conclusions, interpretation, and presentation of experimental results.

- Developing all forms of experimental designs

- Designing experiments for characterization, qualification, and reliability testing of new manufacturing processes and materials

- Utilizing statistical analysis software packages (Minitab, Excel, and Statistical) to produce experimental designs and analyze results.

Experience:

- Design reliability testing experiments and analyzed data for a joint project with Motorola. To test a new circuit board low residue soldering process.

- Design process characterization experiments and analyzed data for AC Rochester. A division of General Motors, for their new low residue soldering line.

- Develop full test plan including several experimental designs and analyzed data to test low residue soldering process reliability across several manufacturers, equipment, and materials.

- Design series of experiments and analyzed data to determine the effects of smoke on electronic circuitry for NRC.

- Design series of experiments and analyzed data to determine influential factors on customer satisfaction for Intel manufacturing line.

- Develop test plan and experimental design for experiment to determine major sources of variability in Neutron tube subassembly manufacturing process.