Visual Management is a mechanism or management method, which can clarify at a glance, what problems are occurring on the site, it enables problem solving as well as appropriate countermeasures. This is directly aimed at creating production efficiency and reducing costs, simplifying the management business of managers and supervisors, and improving their efficiency and improving the abilities of site managers and supervisors.

At the same time, the ultimate goal is to improve the management level, optimize the organizational structure, improve production efficiency, and create a bright and simple and dynamic business characteristic.

The concept of visual management

Visual Management (VM) is famous for its key relevance, as it provides a visual representation so that management can get an idea of the actual situation at a glance. Specifically, this management method is use to detect defects in production and production-related activities.

This method uses various visual perception information with intuitive images and appropriate color to achieve the objective of planning production activities on site and improving labor productivity. It takes visual cues as a basic medium and openness as a basic principle and makes managers’ needs and intentions visible to everyone as much as possible, so as to promote self-management and self-control.

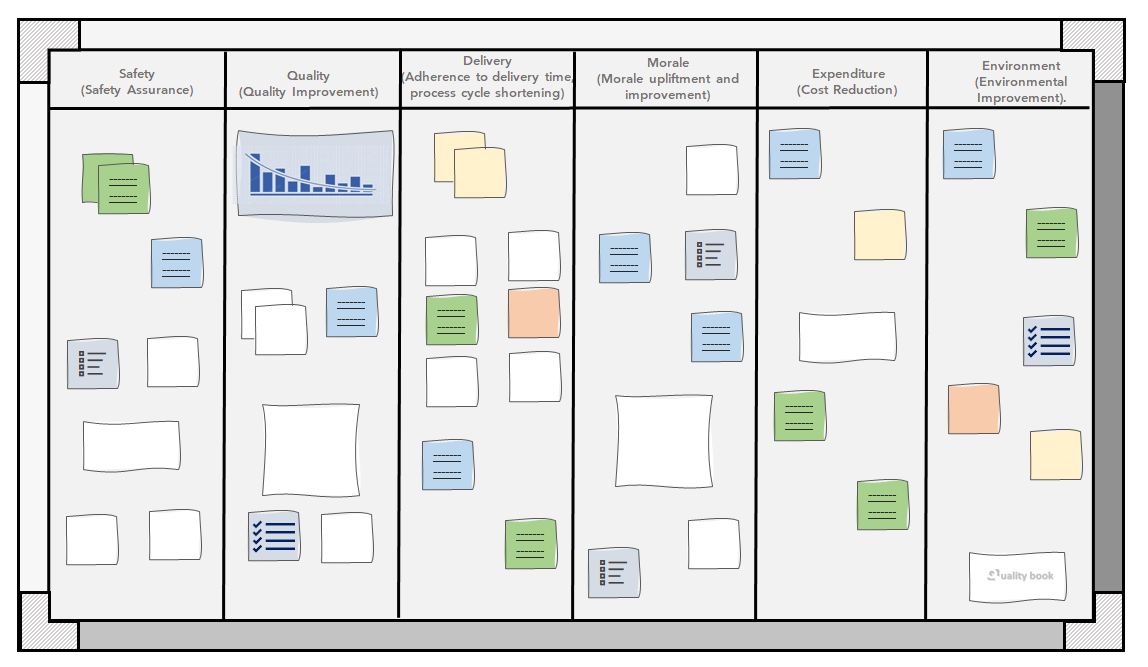

Visualize the tasks and impacts of visual management

The task of visual management is to improve “S, Q, D, C, M, E”. which is a process that promotes on-site improvement. The ones to focus on are as follows:

S: Safety (Safety Assurance)

Q: Quality (Quality Improvement)

D: Delivery (adherence to delivery time, process cycle shortening)

C: Expenditure (Cost Reduction)

M: Morale (morale upliftment and improvement)

E: Environment (Environmental Improvement).

How it works?

By standardizing everything on the job site through the use of visual management tools, everyone in the field, especially managers and supervisors, can detect anomalies, waste, and problem points in a timely manner and ensure that appropriate measures can be taken in a timely manner.

To implement visual management, the following tools and methods can be use:

Signal lights.

It is a tool use to notify managers when an exception occurs during the process, and can be divide into pronunciation signal lights, abnormal signal lights, operation indicators, and progress lights.

Color line/tape.

Use color to identify areas, parts, etc. to ensure that the site is standardize and orderly, so as to facilitate the timely detection of abnormalities.

Management board.

A display board use to reveal the production status and progress of the production line, and record the production performance, equipment operation rate, abnormal reasons (line stoppage, failure), etc.

Charts.

For example, the production instructions for key processes and operations are hung on the process or suitable parts to guide production operations.

Samples.

Display the present in a prominent position so that the operators on site can understand it at a glance.

The reminder board

Locate in a conspicuous place, is used to record the information that needs to be remind to prevent omission or forgetting.

Bulletin board

Use to timely release various management information, convenient for workers to understand in time.

Signage

The information is made into a brand with suitable materials to hang or post.

To implement visual management, we must grasp three basic principles:

Visualization:

– Through visual information and tools, make the management content and requirements visible;

Transparency

– What needs to be seen but not revealed, must be visible;

Boundaries

– Identify normal and abnormal situations and make them clear at a glance.

To implement visual management, we must not only do superficial work, but must start from the enterprise itself, grasp the key points, and gradually carry out it in an orderly manner.

In the process of implementing visual management, the basic requirements of “unify, simple, distinct, practical and strict” should be achieve:

Unified, that is, visual management should be standardize and eliminate all kinds of clutter;

Simplicity, that is, all kinds of visual display signals should be easy to understand and clear at a glance;

Vivid, that is, all kinds of visual display signals should be clear at a glance, place appropriately, and the on-site personnel can see clearly;

Practical, that is, not fancy, try to save costs, produce more results, pay attention to practical results;

Strict, that is, employees must strictly follow and implement the regulations issue, correct mistakes immediately, and clearly reward and punish.

Methods & Tools for implementation of Visual Management

Red card

Red card, suitable for finishing in 5S, is the basic starting point for improvement, use to distinguish non-essential activities in daily production activities, and the activity of hanging red cards is also known as red card combat.

Kanban

It is used in the 5S Kanban battle, and the basic status of the items use is placed. Where is it locate? What to do, how much, who is responsible, and even say, who manages and other important projects, people can understand at a glance. Because of the promotion of 5S, it emphasizes transparency and openness, because visual management has a prerequisite, that is, the elimination of black box operations.

Signal lights or abnormal signal lights

At the production site, the managers of the first line must know at all times whether the operator or machine is operating normally, whether it is working normally, and the signal light is a tool use to notify the management when an exception occurs in the process. Types of signal lights:

Pronunciation signal lights

Suitable for material request notification, when the process of materials use up, or the supply and demand signal light on, the amplifier will immediately notify the delivery personnel to supply immediately and in time, almost all factory supervisors must be very understanding, signal lights must be on at any time, signal lights are also an important item in Kanban management.

Abnormal traffic lights

It is use for abnormal occasions such as poor product quality and abnormal operation. And is usually install in long production and assembly lines in large factories.

Generally, set red or yellow such two signal lights, control by employee. When the parts are use up, there are abnormal products and machine failures, often affect the completion of production indicators. At this time by the employees immediately press the red light button, and so on the red light on, production management personnel and plant directors to stop the work in hand, immediately go to the site. To investigate and deal with, after the abnormality is eliminate, the management can turn off this signal light, and then continue to maintain operations and production.

Operation indicator

Check the status of the operation, machine start, changeover or stop that shows the status of the equipment. When it is stop, it also shows why it was stopped.

Progress light

It is relatively common, install in the assembly line, in the manual or semi-automatic production line, its interval between each process is about 1-2 minutes, for the control of the assembly cycle to ensure the output. But it is use for jobs when there is a length of several minutes between beats. As far as the operator himself, he grasps the progress and prevents the slowness of the operation. Progress lights are generally divide into 10 points. Corresponding to the steps and sequence of the job, the standardize procedure, its requirements are also relatively high.

Operation flowchart

Operation flow chart, which itself is a concise instruction that describes the focus of the process and the sequence of work, also known as a step diagram, is use to guide production operations. In the general workshop, especially the workshop with more complex processes. There must be an operation flow chart in Kanban management. After the raw materials come in, the first process may be signing. The second process may be pointing, and the third process may be conversion, or conversion, which is call the operation flow chart.

Negative teaching materials

The negative teaching material, generally it is a combination of existing objects and Plato’s representation. It is to let the operators on the scene understand, but also know his bad phenomena and consequences. It is generally place in a prominent position with many people. So that people can understand at a glance that this cannot be use normally, or cannot be operate in violation of regulations.

Reminder board

Reminder board to prevent omissions. Forgetfulness is human nature, it is impossible to put an end to it, only through some self-management methods to minimize omission or forgetting. For example, at the entrance and exit of some workshops, there is a board. How many products will be deliver where and when today. Or what products must be produce when. Either there is a leader who comes to inspect, there is an inspection at two o’clock in the afternoon, or a certain leader comes to inspect.

These are collectively refers to as reminder boards. Generally speaking, the vertical axis represents the time, the horizontal axis represents the date, the time interval of the vertical axis is usually an hour. A day is distinguished by 8 hours, and every hour is each time period to record normal, bad or defective products, let the operator record by himself. The reminder board is counted once a month, summarize in each month’s regular meeting, compare with the previous month to see if there is progress. And determine the next month’s table of contents, which is another function of the reminder board.

Area line

The area line is to draw the semi-finished products in the place or passage and other areas, which are mainly use for sorting and rectification, abnormal causes, line stop failures, etc., for Kanban management.

Warning line

Warning lines are color paint lines painted on the ground that are use to indicate the maximum or minimum inventory in warehouses or other items, and are use in Kanban operations.

Bulletin boards

The notice board is a prop for timely management, that is, an announcement, or a kind of letting everyone know, for example, this afternoon meeting at two o’clock, the notice board is to write these contents.

Production management board

The production management board is a display board that reveals the production status and progress of the production line, and records the production performance, equipment operation rate, abnormal reasons (line stoppage, failure), etc., for kanban management.

How to implement it on the production floor?

(1) Strengthening teamwork.

In workplaces where there is no teamwork and motivation, no matter how much management is enhanced, results cannot be expected. It is important to share information through “visual management” and raise the awareness of all employees to participate in factory management.

(2) 5S (Organization, tidying, cleanliness, cleaning, discipline).

It is necessary to implement “visual management” to put 5S into practice and make the factory clean and easy to work in.

(3) Information management (office management).

It is very important for sharing information to make the drawings, specifications, and materials that you want to see immediately available by performing “visual management”. It must be practice before the introduction of computers and IT.

(4) Work management.

It is necessary for supervisors and workers to understand at a glance the attendance status, work content, inspection confirmation, and skill education of workers by performing “visual management”.

(5) Facility management.

By performing “visual management”, it is possible for workers to independently maintain equipment management. Which leads to improve maintenance efficiency and enables early detection and prevention. In recent years, “visible TPM” using TPM (Total Product Maintenance with All Participation) has achieve great results.

(6) Actual product management.

It is important to be able to see what, how many, and where at a glance by performing “visual management”. It is the “basics” of production management that should be address before introducing the Toyota Production System (JIT) without inventory, bar codes, and networks.

(7) Safety management.

Ensuring safety through “visual management” is the first priority in production, and no matter how good the product is, it should never cause injury or death to workers.

(8) Environmental management.

It is important to improve the workplace and improve the environment. So that “visual management” can be carrying out to save resources and prevent environmental destruction.

(9) Process control.

By performing “visual management”, delivery date, lead time, and inventory amount can be understood at a glance in preparation for the introduction of POP (Point of Production Point Information Management) in the future, and process management is perform using commercially available (production targets, progress management boards, work display boards). It is desirable to convert to a computer after visual management has taken root.

(10) Quality Control.

By performing “visual management”, we must strive to maintain and improve quality by making improvements so that mistakes do not occur in measurement and inspection.

(11) Cost management.

By performing “visible management”, we will disclose information on the price of material costs and the amount of damage, so that all employees can work with the idea of self-management and self-management, and strive to improve morale.

(12) Factory profit management.

By conducting “visible management,” we aim to make sure that all employees understand the company’s philosophy and management status, and that all employees participate in manufacturing.

The main contents of visual management include:

Item management with visual management

In daily work, it is necessary to manage a variety of items such as fixtures, measuring instruments, spare parts of equipment, consumables, materials, work-in-progress, finished products, etc. “What, where how much” and “when necessary, necessary items, can be quickly remove and put in” become the goal of item management.

Operation management of visual management

The work in the factory is made up of a variety of processes and people. Is the work of each operation going according to plan? Was it implemented correctly as decided? In work management, it is important to easily understand the status of each operation and process, and whether there are any abnormalities.

Visual management of equipment

In recent years, with the mechanization and automation of the factory. It has been difficult to maintain the normal operation of the equipment by relying only on some equipment maintenance personnel. The equipment operators on site are also require to join the daily maintenance of the equipment. Therefore, the operator’s job is not only to operate the equipment. But also to carry out simple cleaning, spot checking, lubrication, fastening and other daily maintenance work.

Visually manage equipment management aims to carry out daily maintenance work accurately and efficiently such as cleaning, spot checking, lubrication, and tightening, in order to achieve the goal of “Zero failure” of equipment.

Quality management of visual management

Visual management can effectively prevent many “human errors”, thereby reducing the occurrence of quality problems.

Security management of visual management

The safety management of visual management is to “expose” dangerous things and behaviours, stimulate people’s “vision”, awaken people’s safety awareness, and prevent accidents and disasters.

6S management with visual management

Visual management also has many applications in the maintenance of plant environment. 6S is to make management easier to visualize. A good plant environment is maintain, which facilitates daily visualization so that it can be correct. Visual management can also be built using the 6S method.

Basic requirements for promoting visual management

To implement visual management, we must proceed from the actual situation of the business and gradually carry it out in a focused and planned manner. In this process, the basic requirements that should be achieve are unify, simple, distinct, practical and strict.

Description: Unification, that is, visual management should be standardize to eliminate all kinds of messy phenomena. Simplicity, that is, all kinds of visual display signals should be simple and easy to understand, at a glance; Vivid, that is, all kinds of visual display signals should be clear.

The location should be appropriate, and the on-site personnel can see and see clearly; Practical, that is, do not put up flower shelves, spend less money, do more things, and pay attention to practical results; Strict, that is, all personnel on site must strictly abide by and implement the relevant regulations, mistakes must be correct, and rewards and punishments are clear.

Status of visual management and basis for promotion

The management status mention in visual management should have the following three points:

- There are normal and abnormal (or problem points and waste) judgement standards.

- Quickly grasp the abnormal state.

- Prompt and timely action is taken in response to the abnormal situation that has been learn.

The prerequisite for visual management is a practical cycle of “Plan → Do → Check → Act : PDCA”. Which is called the management cycle, and the circular method is the focus. The focus of this loop management loop is to loop through the stages of “P, D, C, A” in a visual state.

Tools for visual management

Its tools generally include charts, management boards, job cards, labels, signs, various colours of paper/tape/paint, etc.