Nowadays, development of production systems using modern methods has become very necessary. In that the most important task of the organization should be to develop the internal processes of the production areas on the principles of lean production. The advantage of such modern approaches is that the manufacturer can formulate production plans focusing on quality improvement, customer satisfaction and staff activation. Value Stream Mapping (VSM) is also a modern approach that helps in identifying and eliminating losses in production areas. Indeed, VSM is the most common tool for identifying losses in the “production flow”, which must include value stream mapping in order to reduce losses while building the flow.

To fully understand value stream mapping, we first need to understand what a value stream “value stream” is. A value stream is the sequence of steps required to provide a product or service to users. Creates own set of processes and steps required for customer’s instructions, requirements and final product. “Value Stream Mapping” helps to better understand this set. Value Stream Mapping Can You Better Understand Where Steps Are What? Where does added value appear? Where not, and most importantly, how can this overall process be improved.

Contents

VSM visualizes each step to provide a structured visual description of each key step and the information associated with those steps that is critical to meaningfully optimizing the entire process, not just one section at the expense of others.

What is Value Stream Mapping (VSM)?

In mainstreaming, each stage of production from product development to manufacturing is mapping within the entire process, including the final stage of production, as well as the processes after the goods are deliver to the customer. This is a graphical representation of all the activities or operations required to guide the product through the main flow.

Value Stream Mapping (VSM) is a tool (method) for identifying economic losses in production processes, reducing technological cycle times, and implementing improvements in the management structure.

In fact, you can cover all the information in a value stream map that can cover all the movements of the production process at a single glance. In particular, may cover detailed descriptions of business processes and production processes, including all material movements, technical processes, operator movements, etc.

“But always keep one thing in mind, value stream mapping always starts with “customer needs” and ends with raw materials for production. which are in reverse order.”

In short, value stream mapping helps businesses to identify weaknesses in processes and identify opportunities for their improvement. Which ultimately leads the business to focus on: improving quality and reducing cycle time of processes.

How to Create VSM? {Value Stream Mapping Process}

First, we have to understand that a value stream map (VSM) is a schematic description of the production processes used to produce a product. The customer is considered to be the end user. Here in VSM we can see all the stages of production in detail, which covers from raw material to delivery of goods to the customer.

Hence, when we create a value stream map, these things must be taken care of. The step-by-step information is as follows:

Determine the goals of improvement.

Before you start value stream mapping, you need to consider improving or expanding all of the production processes, while at the same time setting improvement goals. It is one of the most important processes to define the targets for improvement. It is natural that the team preparing the production processes and value stream mapping knows what the improvement goals should be which may be for aspects like safety, quality, supply discipline, productivity, speed, flexibility, controllability or cost etc.

Select the appropriate product group.

As you know, creating a VSM for every product is not efficient or practical. When a product actually requires a VSM, it is appropriate to create a product group and create a VSM for it. It is real that many challenges can be faced when creating a VSM to select a group. Because each product’s requirements and manufacturing processes may be different.

But it is a practical and accurate way to show a value stream map showing all the common and relevant stages and routes of a product. It should also be understood that since it is not possible to create its own VSM for each product, the VSM should be prepared by the stages of the processes that give the product the widest flow.

Prepare the phases in reverse order.

Make sure to put the customer first when you are creating a value stream map. It means showing the entire production process in reverse order, such as delivery of goods to the customer, packing of goods, production processes, purchase of raw materials. Also, all stages of each work flow should be marking in sequence.

Describe the movement of material over a stream

As you know value stream mapping covers visual representation as well as information flow. Therefore, all elements of production flow such as information flow and its planning, planning orders, flow of goods in processes, as well as communication with the customer should be integrated. In particular, the management of the flow and quantity of goods at each stage of production.

Fix process parameters

The map integrates the key quantitative indicators of each phase. like:

- All time cost of manufacturing products

- Equipment downtime

- Percentage of Defects

- Efforts of employees

- Quantity of material stock

- Information on ingredients

- Details of work in progress, if any, in production area

- Information on finished products

Parameters are selected individually based on the goals and specifications of a particular project. In the process of filling out the VSM, it is important that all team members make their own edits so that the end result objectively reflects the current state.

Find and quantify losses in business processes.

Based on the information obtained earlier, all such processes should be covered in the map, in which the damage has been identified. Which can be solved through this map, and the achievement of the elimination or reduction improvement goals will be easier. A value stream map is a tool to help bring the Lean manufacturing philosophy to life. VSM allows you to collect complete and visual information about the state of business processes, which helps to effectively develop ways to optimize them.

How does Value stream mapping work?

As you know VSM is a systematic graphical visual map of production processes and other processes. It contains detailed information of all processes, material flow, resource and manpower related structure.

This framework can identify losses in processes, as well as help in optimizing processes. So now let us know how this work is done.

It specifies the processes of production.

When you map the key stages of a manufacturing process onto a VSM, you can see that all actions, resources and manpower involved in those processes can be quantify and utilize at each stage. So that improvements and changes can be understood and followed.

Explains the scope for observing phases.

It is clear that, when you show the production processes on VSM, it is clearly understood that all the processes – from the buyer to the supplier – can be a description of the product and its entire work flow. In short, from the sale of goods to the purchase of raw materials, the starting and ending points of the materials are included [in reverse order]. It becomes possible to observe a series of these processes. It can display information on time, quantity, quality and more.

Using the information

- It contains complete information about the flow at every stage of the process.

- This includes information on production processes – how long each stage will take, or how long it should take to complete.

- Manufacturing process cycle time – which can be expressed as the time that elapses between the completion of two products in a row at a stage.

- Information that may be the result of processes can be expressed as a percentage, so that it is easier to compare other products.

Dependence of flow of processes.

As you know, the dependency information of the flow of processes is the basis of VSM. Generally, it indicates the relationship between actions with direction, and characteristics. Based on such interaction, the information obtained by VSM proves useful, making it easy to detect negative steps or actions.

Explanation using timeline

Timeline is an important part in VSM.

Within which the total time – mean loss time + useful time – can be represented by a solid line (time elapsed) or a multi-layered line.

Loss of time – time lost in waiting, or due to delay etc.

Useful time – time used for production

Value stream mapping (VSM) is a truly idiosyncratic task, meaning that there is no standard for it. But the basics are kept in mind, which is completely dedicated to the production facility.

How Value stream mapping useful?

As you know, today’s business is becoming more and more competitive than ever, along with increasing options for consumers.

So, it is clear that any business has to work faster and be more efficient than before.

- Hence such systems have to be set up for the manufacturing sectors to better protect the customers. For that VSM is an excellent system that makes development processes more qualitative and systematic. VSM is now more efficient to better coordinate with customers, internal systems and third parties.

- Through mapping it is hope to understand what the customer wants? what is valuable to them? what do they need? and how to achieve it most efficiently.

- Understanding quality from the customer’s point of view is invaluable to process efficiency and product quality.

- Mapping can also be extremely useful for an integrated perspective that includes managers, team members, leaders, and stakeholders who are internal and external customers.

- Through VSM one can easily get a more holistic understanding of production processes as well as individual participation in the entire process and their roles in it, their contribution to production. That add perspective helps them each see their individual contributions to the overall product delivery process as more meaningful, valuable, and important.

- It is a matter of fact that in any manufacturing sector, even though the manager understands that every employee follows the prescribed procedures, the reality is very different. So only a mature and sustainable process can solve this. For that VSM simplifies the processes, as well as makes it easy for the manager to know who is working in which processes. What is the workload of the employees?

- Focusing on the changing factors, suggest ways to improve them.

- Unplanned processes, tasks and projects can be linking to the mainstream, resulting in a complete picture for the manager.

VSM shows the current conditions of production processes very easily and systematically. When a business is making changes in its growth cycle, a simple baseline is a great way to compare the future state.

Creating a value stream map

As you know, value stream map is more complex in its design than other flow maps, but it is more useful for detecting and analyzing losses. Also provides examples of visual representations of VSM processes. But, determining which process to map to will depend on the manufacturer. So here is an example given below along with symbols for mapping and information about it.

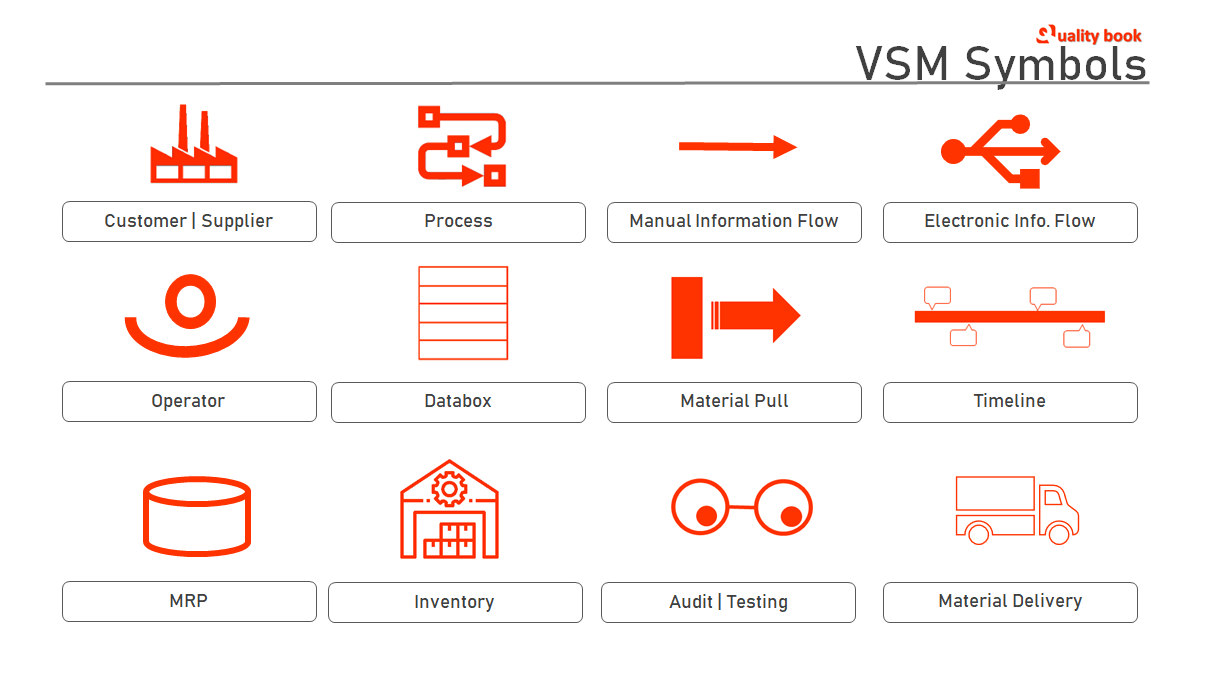

The following symbols are used to develop a process map:

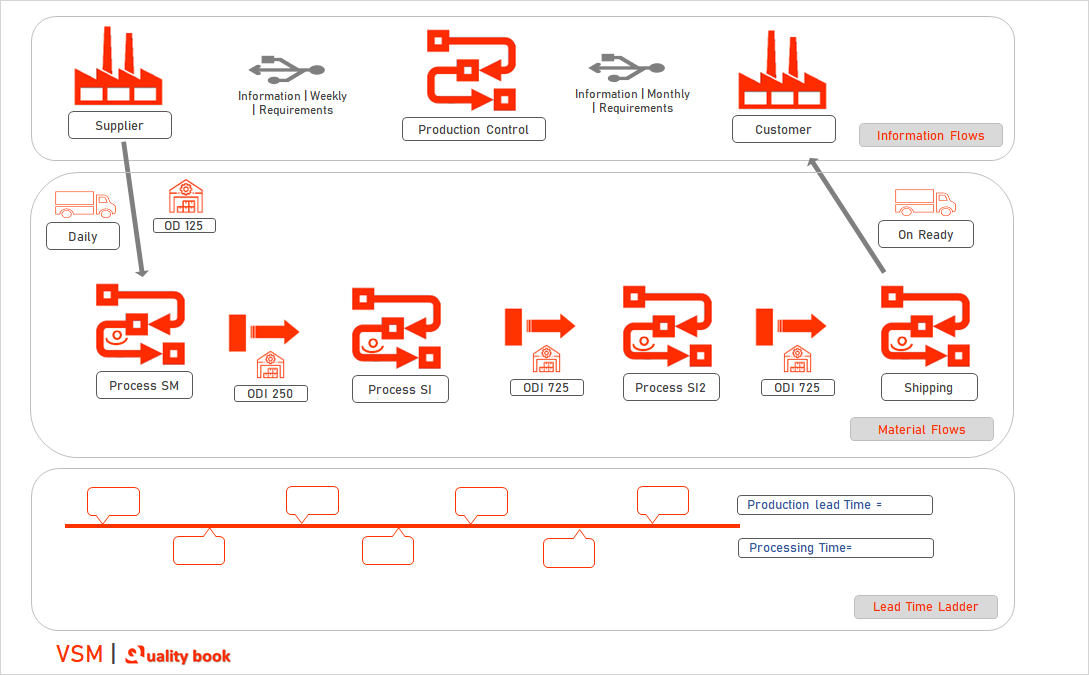

Value stream mapping Common Flow

As you know, VSM displays all the information from start to finish of any business. However, it is still important to understand some standardize components of VSM. So, it can be modify to achieve certain goals. While making the map keep in mind that VSM has three main streams. Information flow, product flow and lead time. This flow map makes it easy to explain which direction the flow goes.

Information flow

The map shows the exchange of information within this area which may be for production processes, raw materials or other materials. There is only an exchange of information, which may be between the customer and the manufacturer, with the manufacturer and the seller of the goods, or between any other party or parties.

The purpose of this area is to focus on the points of exchange, storage and distribution of information. Within this there may be many levels of detail and many integrated systems, each of which can represent process information.

Production flow

It is obvious that production processes are the main stream for production, so this map shows the production flow methodically and with complete information, in which all the supporting processes should also be shown in detail. Within this area all the steps from the full scope development life cycle of the product to the delivery of the goods to the customer can be represented. Through this map, depending on the main objectives of the business, each process can be focused on specific areas. In short, depending on the main objectives of the business, which process is important, it can be as detailed or generalized as needed.

C.T. [cycle time]

Very useful in maps is cycle time, which is the average time interval it takes for a product to pass through a stage or to complete a stage on a product part.

Preparation Time [S.T.]

Based on the step in the map, the time taken to complete the stages of production and the preparation time are humanized. Based on this it may be time to prepare the required test environment.

Uptime, Accessibility, Uptime (%)

It is very important that when there are specific mathematical instructions and information requirements for production processes or systems, the map should show the information that is active or available. For our scenario, this metric can reflect system availability or employee availability.

Lead Time [ Total Processing Time] – L.T.

Within the map, the total process time is shown as the time taken in all the processes from the initial processes of the mouth to the final processes of the product.

Example VSM

Key steps to create a Value stream mapping.

Focus on what’s important.

When you start working for VSM, keep in mind that this first step is very important in the whole VSM. The tasks you want to complete, to improve, or to identify losses, all begin with these steps. We should start by clearly defining the task we need to solve.

By directing the map to the main objectives, all objectives can be clearly understood, as well as adding information that will determine the area and display process. Typical goals may be speed of processes and tasks, improved quality, improved management, compliance, efficiency.

In short, understand what is required before building a VSM? Who needs to focus on? How to make? And we do what we want.

Select a team for Value stream mapping.

Remember, if you think we need to create a VSM, and we did, this understanding will not work. One thing to understand is that VSM is different for every business, so first understand what your needs really are? What do you want to find out? What positions should be given importance in your processes? And who among all the employees is suitable for these tasks?

Team selection is an important task for VSM. So before choosing a team, it is necessary to select employees who are connected to the streams, experienced, and can directly influence the processes. This requires understanding the levels of processes, identifying where growth, change or loss occurs.

Get information from the customer

When you are creating a VSM, it is very important to visit the customer first and collect information from them. Especially where the work is done, that is, where the customer is working using our product should be understood. Understand from the customer why they need our product, how they use it? And understand all their processes, see what works for them and what doesn’t.

By doing so, you can understand our product, customer needs and improvements from a more holistic view of the process. It is important to do this through a “customer’s perspective” mindset of how each step of the process benefits the customer. So, value stream mapping will be more reliable and beneficial.

Identify the initial value stream.

If the beginning is auspicious, everything becomes auspicious. Identify starting points for VSM to give our team a starting point. Which will help to start for the team. The key here is to outline just the basics of the process. Then necessary additional details should be added, as required. By doing this, the team will not be burdened with the task of finding a solution. With that, how do they see the flow? And does it work? Also provides its first raw image. Also allows for faster progress towards better discussions.

Group Mapping

Any task can be successful with the cooperation of the team members, so it is very important that the value stream mapping is prepared by the team. Each member of the team is an expert in their own area of competence as well as their department of processes, which helps in creating the map. A team approach provides different perspectives on the changes needed and how best to implement them.

Keep revising the value stream map as per current status

This is a very important aspect that when making a VSM, or if a VSM is made, it is very important that it is current. As conditions change over time, with it the current cycle time, full flow time, availability time, internal processes, manpower etc. The VSM should be improved over time, so that the current state will be useful in the future, and indeed the ground state can be easily understood.

Keep the value stream map focused on the goal

There is actually a lot of information inside the map, but it is very important that the VSM focuses more on the target. In VSM it should be clear what is the basis and purpose of VSM? Also, there should be a clear description about it.

Conclusion

VSM is a tool through which you can graphically represent complex processes easily. Especially production processes that are complex, important and important information for production goals can be displayed in the map. In fact, this map is an accurate description of the flow of processes, providing ease of locating defects and losses.